Download Printer Friendly PDF Version

|

pH / ORP / ISE Process Measurement & Control Systems |

|

Product Focus # 2 - Sensors for Myron L Meters-(July 2008) |

|

Features · Guaranteed Longest Lasting Sensors Available with performance guarantee*

· Sensors are compatible with most existing pH/ORP Meters, Transmitters & Analyzers**

· Application Specific Engineering results in optimum Lifetime & Performance***

· Integrated Temperature Compensation, Preamplifiers & Solution Ground Elements

· Solid State Reference System offers superior resistance to Fouling & Dehydration

· Applications such as Acid/Fluoride, Hi-Temp, Saturated Sodium and Sulfide Resistant are available as standard options

· Custom Applications are available, often at no additional charge

· Most Installation Styles are Supported Including: Immersion, Twist Lock, Valve Retractable & Sanitary

· Available in a wide range of plastics, from inexpensive CPVC & PVC to thermally & chemically resilient RYTON® thermoplastic

· High Pressure Applications up to 100 psi for Valve Retractable & 150 psi for Inline Installations can be supported for continuous use

· Operating Temperatures from -30 to +150 ºC (-22 to +302 ºF) can be supported for continuous use |

PRODUCT FOCUS # 2

Replacement pH & ORP Sensors for Myron L Company pH & ORP Transmitters, Monitors & Controllers

Competitively Priced High Performance Solid-State pH & ORP Sensors that can retrofit almost any existing Myron L Company pH/ORP Transmitter and Controller

The Problem A company wanted to modernize its pH measurement equipment to use long lasting solid-state pH sensors for environmental pH & ORP measurement applications for agriculture, water and wastewater but they had a broad install base of older Myron L pH transmitter that required a particular type of pH sensors that was not readily available from most suppliers except the OEM manufacturer (in this case Myron L). They had a wide array of pH & ORP monitors and controllers from the MyronL 720 Series II meters including the 721II, 722II, 723II & 724II for pH and the 726II, 727II, 728II and 729II for ORP. Although these older analog pH analyzers, transmitters and controllers worked well in many cases, the pH sensors had to be replaced and cleaned frequently and did not enjoy the success that one would expect in typical water and wastewater treatment applications. The customer used a wide array of MyronL pH & ORP sensors that needed to find suitable modern pH & ORP electrode replacements including P72S, P72D, P72LC, P72F, P74S, P74D, P74LC, P74F ½” MNPT and ¾” MNPT pH sensors and the O72S, O72D, O72LC, O72F, O74S, O74D, O74LC, O74F ½” MNPT and ¾” MNPT ORP sensors.

These single and double junction pH electrodes use the traditional type of porous reference gel technology that can be quickly depleted by high flow rates and temperatures and fouled with contaminants. These pH probes and ORP probes use an special type of integrated temperature sensor and preamplifier that make it difficult for customers to find suitable retrofit replacement sensors. ASTI has extensive experience retrofitting a wide range of Myron L pH Monitors & Controllers such as 720 Series II. In addition, the older type Myron L pH and ORP electrodes cannot be stored dry for any prolonged period of time as the porous reference element will dry out and not recuperate with simple reconditioning. The customer desired to not lose pH sensors or ORP sensors due to accidental dehydration (left stored dry in storage or process) or due to improper handling (sensitive to breakage with small lab-grade pH and ORP glass element).

The Solution The specific color-coding for the Myron L type pH and ORP sensors is also used by direct replacement and retrofit pH and ORP sensors. ASTI adheres to this existing wiring schematic so that any retrofit pH sensors quoted will serve as a DIRECT REPLACEMENT for the existing sensors (just wire it up per the normal MyronL schematic for your meter).

Integrated, sealed, “maintenance free” solid state pH and ORP sensors that could retrofit to all of the existing Myron L pH and ORP Monitors & Controllers were required. Flat pH elements were made available for process were build-up was problematic (Model 2312 replacing P72F and 74F). The non-porous conductive polymer solid state reference double junction (triple junction available) reduced the cleaning requirements as compared to the P72S, P72D and P72LC pH sensors and the P74S, P74D and P74LC ORP sensors and also made the sensors more resilient to occasional periods of dehydration. The customer was able to use strong (half-dilute) hydrochloric acid to remove any deposits and thus minimized breakage by reducing the frequency of mechanical cleaning. Service lifetime improved considerably and maintenance was reduced, with little change in the unit price of the individual sensors. The result was the ability to reduce operational costs considerably without the expense and inconvenience of changing transmitters.

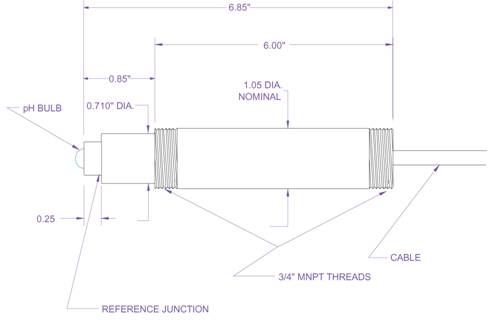

The Typical pH Sensor Used: Model: PNZ 2012-MYRONL-25-TL pH Sensor Compatible with most Myron L pH Meters Description: ¾”- ¾” MNPT Immersion CPVC Bodied Low Impedance solid state pH Sensor with integrated Myron L Compatible Temperature Element & integrated Myron L compatible preamplifier; 25 feet of cable; tinned lead wires only to connect directly to most Myron L meter.

The Typical ORP Sensor Used: Model: PN 2812-MYRONL-10-TL ORP Sensor Compatible with most Myron L ORP Meters Description: ¾”- ¾” MNPT Immersion CPVC Bodied solid state ORP Sensor with integrated Myron L Compatible Temperature Element & integrated Myron L compatible preamplifier; 10 feet of cable; tinned lead wires only to connect directly to most Myron L meters

|

|||||||||||