Download Printer Friendly PDF Version

|

pH / ORP / ISE Process Measurement & Control Systems |

|

Case Study # 12 – Chlor-Alkali Saturated Sodium - (January 2004) |

|

Features · Guaranteed Longest Lasting Sensors Available with performance guarantee *

· Sensors are compatible with most existing pH/ORP Meters, Transmitters & Analyzers **

· Application Specific Engineering results in optimum Lifetime & Performance ***

· Integrated Temperature Compensation, Preamplifiers & Solution Ground Elements

· Solid State Reference System offers superior resistance to Fouling & Dehydration

· Applications such as Acid/Fluoride, Hi-Temp, Saturated Sodium and Sulfide Resistant are available as standard options

· Custom Applications are available, often at no additional charge

· Most Installation Styles are Supported Including: Immersion, Twist Lock, Valve Retractable & Sanitary

· Available in a wide range of plastics, from cost effective CPVC to thermally & chemically resilient ULTEM® and PEEK thermoplastic

· High Pressure Applications up to 100 psi for Valve Retractable & 150 psi for Inline Installations can be supported for continuous use

· Operating Temperatures from -30 to +150 ºC (-22 to +302 ºF) can be supported for continuous use |

Case Study No. 12 – pH Control in Chlor-Alkali Manufacturing

Saturated Sodium & Dissolved Gas Resistant pH Sensors

The Problem

A chlorine dioxide (bleach) manufacturing company wanted to improve their pH control, reduce sensor replacement and minimize maintenance time. Corrosive ClO2 dissolved gas was causing frequent sensor failure at the reference half cell, resulting in constant drift and eventually sensor removal. The saturated brine solution caused problems for many pH glass formulations, resulting in large offset errors from standard calibrations.

The stray current, something that can occur frequently in many chlor-alkali processes, caused problems for the silver/silver chloride half cell inside the pH and reference elements, resulting in early expiration of the sensor. Since instrumentation was widely standardized throughout the plant, changing out the pH instrumentation would be very cost prohibitive. Most pH sensor manufacturers require customers to use their make of transmitters and do not retrofit existing pH instrumentation.

The Solution

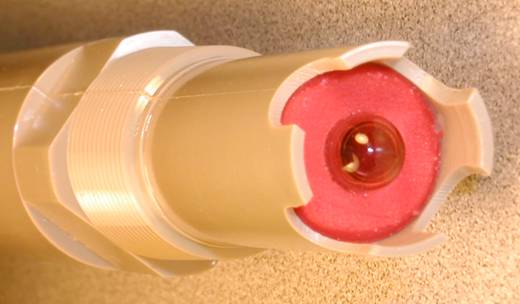

The solution to these manifold problems was complicated. The thermoplastic PEEK was employed due to its excellent resistance to dissolved oxidizing gases and strong electrolyte solutions. A truly saturated sodium resistant glass was selected to improve measurement accuracy. The pH element was fabricated so as to be hysteresis resistant to minimize the effect of stray electrical current. A triple junction reference system was employed in addition to a dissolved gas resistant solid state polymer reference junction.

The suitable electronic components were selected to directly retrofit with the existing transmitters, saving the customer the cost replacing their existing pH instruments. All of these improvements were provided at a price that was quite competitive to the previous pH sensors used. The sensor lifetime was more than doubled from previous pH sensors.

The pH Sensor Used:

Model: PNCTJHR 6141/6941-3000-20 pH Sensor Description: ¾”-1” MNPT Immersion PEEK Bodied High Temperature, Saturated Sodium and Hysteresis Resistant pH Sensor with Triple Junction Reference System; integrated with Balco 3K Temperature Element; 20 feet cable to connect directly to TBI Analyzer/Transmitter

Choosing the Correct pH/ORP Sensor

1. Choose a sensor body type that suits the physical parameters of the installation (refer to the Configurations Portion of pH/ORP and Ion Selective webpages). 2. Choose a sensor that suits the process application, temperature, chem istry, and physical parame ters of the installation (refer to Sensor Selection Guides and call factory or local sales agent for support) 3. Choose a sensor housing material that is compatible with the process chemistry, temperature & pressure (refer to Chemical Resistance Charts as posted under the Technical Documents portion of the website). 4. Select suitable temperature compensation element, solution ground & integrated preamplifier based upon the mating pH/ORP Instrument (refer to Electrochemical Instrumentation Page & ask for factory support). 5. Specify the required cable length based upon installation location (refer to Part Numbering Guide).

* Subject to application qualification and review by an approved ASTI sales agent and/or factory. Performance guarantee is posted on the ASTI online application questionnaire page. ** See list of supported pH/ORP/ISE Instruments webpages as posted on the ASTI website. *** Completion of Application Questionnaire form is required. Other restrictions may apply. |

||