AST-DO-UNIVERSAL Galvanic Dissolved Oxygen Sensors for Inline, Immersion, Submersion, Sanitary & HOT-TAP Installations Rugged Industrial High Stability Thick Membrane is ideal for Continuous Measurement in Tough Applications such as Processes with Abrasive Slurries, High Levels of Organic and Biological Content & Solutions with High Turbidity

Close-Up on galvanic DO measuring cell for dissolved oxygen sensor in convertible configuration

- Disassembled galvanic DO measuring cell ready for rebuilding

- Cathode & anode on front tip of sensor are shown to the bottom right

- High stability thick membrane installed into cap is shown immediately above

- Membrane & electrolyte solution are easily replaced by anyone in just minutes when required

- Virtually unlimited sensor lifetime with rebuildable DO cell ensuring very low cost of ownership.

AST-DO-UNIVERSAL-CONVERTIBLE dissolved oxygen galvanic DO sensor shown in convertible without preamplifier with shielded black composite cable (max 15 meters, 50 feet cable). In the with integral analog preamplifier configuration (not shown) up to 100 meters (330 feet) total cable length can be supported. Other options available but not shown are waterproofing options for fully submersible installations without the use of an immersion tube. In addition the Q7M waterproof NEMA 6P rated quick disconnect snap connector is available for DO sensor in the with integral preamplifier configurations (see further below). AST-DO-UNIVERSAL dissolved oxygen sensors are also available in twist lock quick disconnect bayonet style for inline installations for easy removal & insertion from process for cleaning. Sanitary tri-clamp & HOT-TAP valve retractable installations supported using same 316SS sensor holder installation hardware as for the pH/ORP/ISE sensors.

The AST-DO-UNIVERSAL is a robust thick high stability membrane covered self-polarizing active style galvanic cell that generates a millivolt electrical signal proportional to the oxygen pressure it senses. The AST-DO-UNIVERSAL probe is very rugged, easy to use and proven solution for measurements from tough industrial, municipal, environmental and aquaculture and for other difficult service condition applications.

The AST-DO-UNIVERSAL-CONVERTIBLE configuration is suitable for inline, immersion or submersible type installations (see sections below for more details & specifics).

Drawing above is shown with standard 1.50 inch insertion depth for inline use. Available up to 3.50 inch insertion depth as a special order option.

Special Features Highlighting Unique Technical Advantages of AST-DO-UNIVERSAL Dissolved Oxygen Sensors

- Thick-wall TEFLON™ (PTFE) membrane ensures very high stability, low-drift and high durability in aggressive industrial applications & minimizes frequency of membrane replacement

- No special maintenance needed. Just wipe the membrane periodically as required.

- Galvanic dissolved oxygen cell with true zero means only a slope (span) calibration performed clean and dry in air is required. No wet solution calibration is ever needed and so no calibration solutions are ever required for calibration.

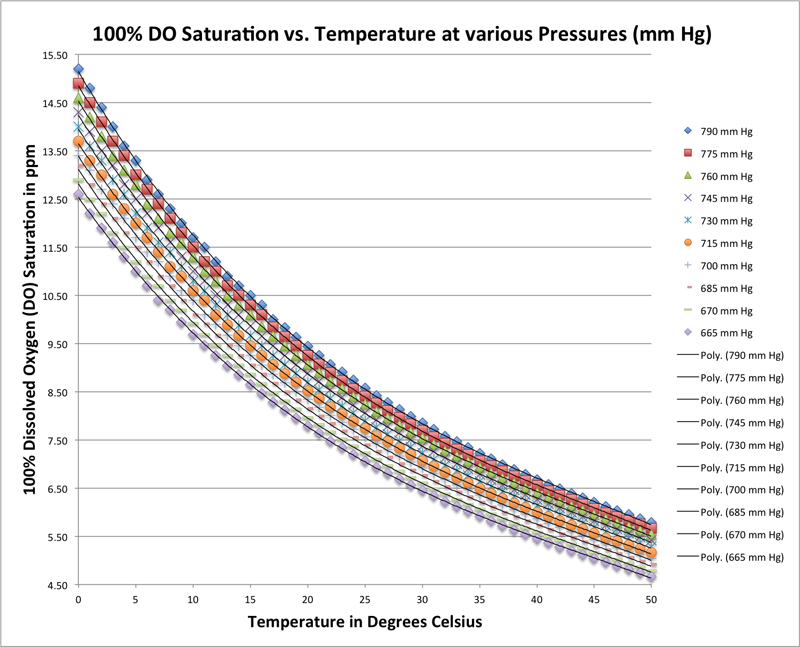

- No look-up tables are needed since the 3TX-DO transmitter computes the dissolved oxygen ppm value associated with the 100 percent saturation dry in air condition used for calibration at the current measured temperature (from integral Pt element) and the user entered atmospheric pressure. The automatic calibration mode autoreads the mV potential and then assigns the proper slope (span) mV per ppm response for the sensor. Manual calibration mode is also available if the fully automatic calibration mode is not desired.

- Membrane and electrolyte solution are simple to replace allowing for extremely low ongoing cost of ownership and a theoretically unlimited service lifetime

- The AST-DO-UNIVERSAL DO sensor is not sensitive to hydrogen sulfide gas

- Temperature compensation is built-in & performed automatically inside sensor for reliable readings

- Extremely high stability such that calibration is seldom required with thick rugged TEFLON™ (PTFE) membranes that are easily cleaned. The required frequency of cleaning is low for most applications. If the membrane is damaged, it can be replaced by anyone at very negligible cost in just a few minutes from start to finish.

- Since the galvanic AST-DO-UNIVERSAL dissolved oxygen sensors generate their own mV potential, they do not suffer from cable sensitivity issues that many polarographic (amperometric) DO sensors can that are powered by the transmitter resulting in issues such as warm-up time, drift and related problems.

- AST-DO-UNIVERSAL dissolved oxygen sensors have very little sensitivity to environmental issues such as wind or electrostatics (in dry climates) as well as readily supporting long cable runs or deep submersion installations. The AST-DO-UNIVERSAL in the with integral preamplifier configuration cabling can be bridged across ordinary terminal blocks housed inside a simple waterproof J-box assembly if the cable length needs to be extended.

- Correct measurements with flow as low as 1 cm/s making it suitable for most any common installation type.

- Built-in integrated temperature compensation inside sensor means that temperature sensor is only required if percent (%) saturation is to be computed and for accurate sensor calibration dry in air

- Typical clean water use keeps calibration up to 1 year at a time with membrane lasting 3 to 5 years. More dirty and aggressive applications will need to have membrane replaced more frequently as may be required but calibration need be done very infrequently.

- Spare membranes and internal electrolyte filling solution are available after the ample initial supplies are used at a nominal cost. Standard sensor package contains all parts to operate for a two to five year period for most applications.

- Custom configurations and options available upon request (minimum order quantity may apply).

Core Features of Rugged AST-DO-UNIVERSAL Industrial Dissolved Oxygen Sensors in Convertible Configuration for Tough Inline, Immersion & Submersible Installations

- Inline Insertion depth from 1.5 inches (standard) to 3.5 inches (special order option)

- Ready for inline or immersion use standard, submersible with waterproofing option

- Waterproofing seal option is available for complete cable isolation for fully submersible

installations & applications employing field washdowns and/or moist & humid conditions - Pt1000 temperature element used to compute the % saturation at the current temp

- Without preamplifier configuration has 3 meters (10 feet) of cable standard, Maximum

cable length in this configuration is 15 meters (50 feet) cable submersible to 25 feet - With integral conventional preamplifier configuration also has 3 meters (10 feet) of

cable standard, Maximum 100 meters (330 feet) cable submersible up to 50 feet - Thick rugged PVC jacket on sensor cable suitable for aggressive field use

AST-DO-UNIVERSAL Galvanic Dissolved Oxygen Sensor Specifications

Measurement Range: 0-600 percent (%) saturation, 0-60 ppm range (Lowest Limit 0.1ppm) *

Operating Temperature: -5 to +50 °C (+23 to +122 °F)

Convertible 3/4″-3/4″ MNPT Configuration Installation Styles: Inline, Immersion or

Submersible with immersion tube or waterproofing option installed

Twist Lock Configuration Installation Styles: Inline with 1″MNPT Twist Lock Receptacle

Immersion or Submersible with immersion tube or waterproofing option installed on rear 1″MNPT threads

Sanitary/HOT-TAP Configuration Installation Styles: Inline with mating 316SS sanitary tri-clover sensor holder,

Valve retractable when used with with mating 316SS HOT-TAP hardware assembly,

Immersion or Submersible (with immersion tube or waterproofing option installed)

Temperature Element: Standard with Pt1000 temperature sensor

DO Measuring Cell Material of Construction: DELRIN® (Polyoxymethylene, POM)

Sensor Body Material of Construction: RYTON® R-4-230BL (Poly-Phenylene-Sulfone, PPS)

Dimensions: See drawing above and specification sheet(s) for details

Cable Length Without Preamplifier: Standard 10 feet (3 meters), Max is 50 feet (15 meters)

Cable Length With Integral Preamplifier: Standard 10 feet (3 meters), Max is 330 feet (100 meters)

Measurement Principle: Galvanic cell, self polarizing (a.k.a. active type) & internally self temperature compensating

Signal Response Wetted in Solution: Slope (span) is 1mV to 5mV per DO ppm depending on exact conditions

Signal Response Dry in Air: Typically 10mV to 40mV depending on exact conditions

Signal Response Time: Typically 10 to 20 seconds near ambient (response time is temperature dependent)

Signal Response Resolution: 1% saturation absolute

Signal Response Repeability: Typically ±1% of actual measurement under the exact same conditions

Calibration: Slope (span) determined from automatic dry in air calibration. No zero calibration required for true galvanic DO cell.

Initial Impedance Without Preamplifier: < 2 MegaOhms @ 25°C

Initial Impedance With Preamplifier: < 2 KiloOhms @ 25°C

Flow Requirements, Water: Minimum flow dependent on DO and temperature, typically 1 cm/sec, suitable for most uses

Supplied With: 10 each spare thick high stability membranes with O-rings, 125 ml electrolyte filling solution,

Tool for installation and removal of membranes from ring inside cap

* Contact factory if you plan to measure dissolved oxygen levels above 400% saturation or 40ppm prior to purchase.

Quick Disconnect Snap Connector Option

AST-DO-UNIVERSAL dissolved oxygen sensors with integral preamplifier configuration can be supplied with the rugged field ready Q7M/Q7F NEMA 6P rated quick disconnect snap connector system. See pictures shown below for visualization of this option.

Q7M sensor end of cable snap connector detail close-up view

Q7M/Q7F snap connectors are NEMA 6P rated when interfaced.

Q7F-Xm-TL Female Q7F snap to tinned leads extension cable

Twist Lock Quick Disconnect Bayonet Inline Installation Style Option

The AST-DO-UNIVERSAL-TWISTLOCK configuration is available for use with the twist lock quick disconnect bayonet 1″MNPT fittings for inline installations that may require frequent removal from the process for cleaning. This installation hardware scheme can be visualized and the drawing downloaded from the twist lock pH/ORP configurations webpage.

Sanitary Tri-Clover & HOT-TAP Valve Retractable Installation Style Options

The AST-DO-UNIVERSAL-SANITARY-HOT-TAP configuration is available for use with the 316SS installation hardware for sanitary tri-clover process connections or for valve retractable installations to remove the sensor will the process is still running. The installation hardware scheme for the sanitary tri-clover type processes can be visualized and the drawing downloaded from the sanitary pH/ORP configurations webpage. The installation hardware scheme for the HOT-TAP valve retractable type processes can be visualized and the drawing downloaded from the HOT-TAP valve retractable pH/ORP webpage and the process connection itself can be viewed from the HOT-TAP valve retractable hardware webpage.

Waterproofing Options for Fully Submersible Assemblies

All of the AST-DO-UNIVERSAL configurations (Convertible, Twist Lock & Sanitary/HOT-TAP) are available for fully submersible installations with the use of an immersion tube (a.k.a. standpipe or guiderod) when a suitable waterproofing sealing option is factory installed. The option must be installed at time of order for the AST-DO-UNIVERSAL sensor and cannot be installed subsequently. The recommended waterproofing options are the WPIT sealing which is quite sufficient for most such submersible installation uses or else the WPB or WPH sealing for an even more robust sealing assembly for the most aggressive service conditions.

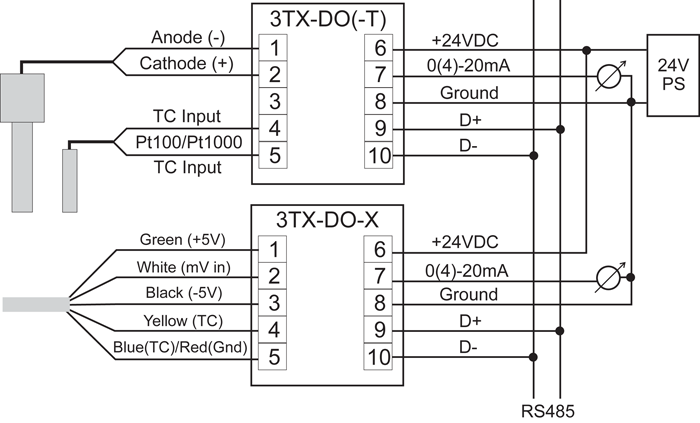

3TX-DO & 3TX-DO-X Dissolved Oxygen (DO) Transmitter Specifications

for AST-DO-UNIVERSAL Galvanic Dissolved Oxygen (DO) Sensors

See main 3TX webpage for all shared common transmitter specifications and documentation

Measurement Range: 0-400 percent (%) saturation, 0-40 ppm range *

Operating Temperature: Usage -15 to +50 °C (Storage -35 to +75 °C)

Without Preamplifier Configurations: Use 3TX-DO-A or 3TX-DO-D Model

With Integral Preamplifier Configurations: Use 3TX-DO-X-A or 3TX-DO-X-D Model

Installation Options for Transmitters: 35mm DIN-RAIL; Wall, Panel or Pipe with IP65 or NEMA 4X Rated Enclosures

Power Options: 3-wire 24VDC or 100-240 VAC 50/60 Hz Line Power Operation

Input Type: AST-DO-UNIVERSAL Galvanic Dissolved Oxygen Sensors with or without integral preamplifier

DO Sensor Input Range: 1.00 to 6.00 mV per DO ppm slope (span) calibration limits; Max 240mV absolute

DO Resolution: 0.01mV and 0.01 DO ppm absolute anywhere in the range

Accuracy: ±1% Excluding Sensor (Ideal)

Temperature Elements Supported: Pt100 or Pt1000 temperature sensor

Temp Range: 0 to +50 °C ± 0.2°C

Available Output: Scalable Isolated Selectable 0-20mA or 4-20mA current loop (Max 500 Ohms load); Optional RS-485 MODBUS RTU

Values Output: DO ppm or % saturation via analog output; DO ppm, % saturation and temperature all sent via RS-485 MODBUS RTU

Output Scaling Limits: Min 0-4 DO ppm, 0-40 % saturation; Full Range 0-40 DO ppm or 0-400 % saturation *

Output Calibration: Trim Offset and Span for analog 4-20mA analog current loop output

* Special order version of 3TX-DO is available for use up to 600% saturation or 60ppm.

Contact factory if you plan to measure dissolved oxygen levels above 400% saturation or 40ppm prior to purchase.

Calibration Performed: Slope (span) obtained from galvanic DO cell clean and dry in air via fully automatic calibration.

The dissolved oxygen ppm value of the 100% saturation dry in air condition automatically determined from values programmed

into 3TX-DO transmitter using temperature value obtained from DO sensor and user entered atmospheric pressure (see below).

Display Features: Absolute mV of connected sensor, DO ppm for 100% saturation condition at current temperature, salinity & air pressure

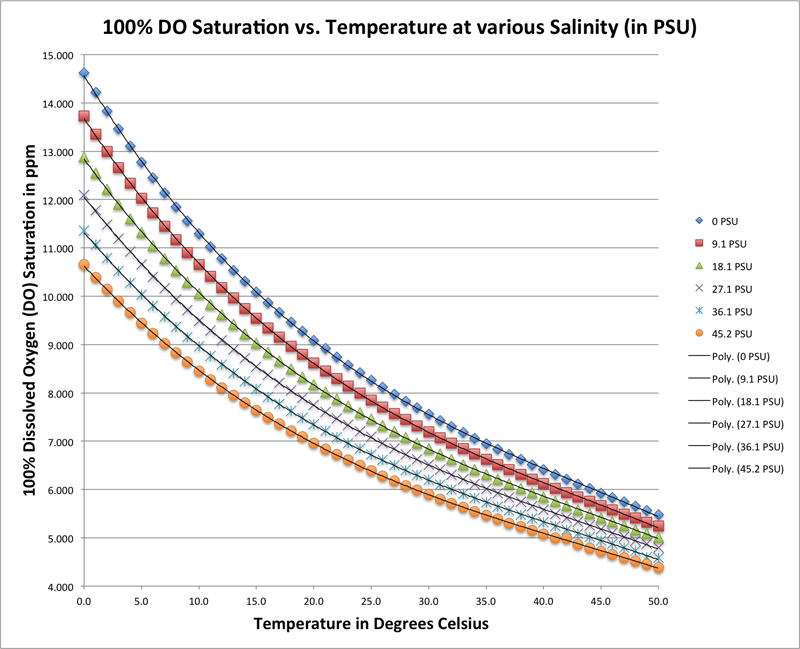

Salinity Correction: From user entered PSU (PPT) salinity together with temperature and pressure to compute percent (%) saturation (see below)

Links for AST-DO-UNIVERSAL Sensor Usage Manual & Complete Literature Package

AST-DO-UNIVERSAL Industrial Galvanic Dissolved Oxygen Sensor Calibration, Usage & Maintenance Manual

Complete ASTI Dissolved Oxygen Sensor & Transmitter Literature Package

Selected Photos for Visualization of Installations

AST-DO-UNIVERSAL dissolved oxygen convertible style galvanic DO sensor with thick rugged removable protective guard securely installed via 3/4″ NPT threads for submersible use with heavy abrasives installations where damage may occur to membrane from large particulates or other abrasive constituents in the measured solution

AST-DO-UNIVERSAL dissolved oxygen convertible style galvanic DO sensor shown threaded into tee with front 3/4″ MNPT threads for inline use. Alternate inline installation scheme is using the 1″MNPT twist lock quick disconnect bayonet style hardware setup to allow for fast and simple removal & installation from process without damaging the cable due to coiling.

AST-DO-UNIVERSAL dissolved oxygen convertible style galvanic DO sensor in the with integral preamplifier and Q7M quick disconnect snap connector configuration. Sensor is shown interfaced to NEMA 6P rated Q7F snap to tinned leads extension cable for convenient removal from field installation for periodic cleaning, recalibration and rebuilding of the galvanic dissolved oxygen cell.

The twist lock quick disconnect configuration of the AST-DO-UNIVERSAL dissolved oxygen (DO) sensor in shown above with a 1”MNPT KYNAR (PVDF) twist lock receptacle installed onto the sensor. This configuration allow for easy insertion and removal from inline installations for cleaning of the membrane, recalibration and rebuilding the galvanic DO cell without coiling the sensor cable. The sensor cable is also available with NEMA 6P rated waterproof snap connectors allows for the sensor to be disconnected quickly and easily from both the process (twist lock bayonet style installation) as well as the mating dissolved oxygen (DO) transmitter.

CLICK HERE for details on SMART DIGITAL HiQDT MODBUS RTU configuration of dissolved oxygen sensors