3TX-HiQ Digital Measurement System for Superior & Cost-Effective Monitoring, Control and Datalogging of pH, ORP & Temperature Process Parameters

“Graduate” to the next stage in field digital

pH & ORP measurements“

- Simplify commissioning & maintenance with smart digital plug and play sensors & intelligent digital transmitters

- Available for both continuous measurements & portable intermittent use

- Lowest startup and ongoing cost of ownership of any digital measurement platform

- Proprietary solid-state reference system for long-life & low-maintenance

- Suitable for abrasive slurries, solvents and high pressures & temperatures

- Sensors are built-to-order allowing for extensive customization

- Robust industrial construction handles the most difficult severe service measurements

- Inline, immersion, submersible, sanitary & HOT-TAP valve retractable style process installations supported

3TX-4MW-3EA-HiQ-pH-PS Triple Channel Intelligent Digital Transmitter Assembly with snap panel connectors shown with Smart Digital ZEUS™ pH Sensor

Quad channel smart digital pH & ORP measurement system in NEMA 4X waterproof 5MF enclosure. Alternate configuration allows for packages anywhere from single channel and all the way up to nine (9) measurements to be performed in a one integrated field package.

- HiQDT SMART DIGITAL MODBUS RTU pH & ORP SENSORS FOR DIRECT CONNECTION TO ANY PLC, HMI, SCADA or any other data acquisition or control device that can serve as the MODBUS RTU master.

- The PLC or HMI employed can either be customer supplied or else ASTI supplied as a part of a turn-key ready system ready for plug and play field commissioning right out of the box.

- ASTI supplied HMI & PLC include options for advanced smart touchscreen controllers with full remote access suitable use in for Class I, Division II hazardous locations as well as Explosion-Proof controller suitable for use in hazardous Class I, Division I EX rated locations. Lower cost instrumentation options also exist for use in safe non-hazardous locations as well as blind installations if no local display is required.

- Smart Digital IOTRONTM pH Sensors & ORP Sensors for Intelligent 3TX-HiQ-pH pH & ORP Transmitters are the most cost-effective & rugged industrial smart digital pH & ORP measurement system available.

- Intelligent management of calibrations with true plug and play digital sensors. Calibrate anywhere and hot-swap interchange the sensor in and out of field service with rugged industrial NEMA 6P snap connector.

- Calibration values are automatically loaded when Smart Digital IOTRONTM pH Sensors & ORP Sensors are connected to Intelligent 3TX-HiQ-pH Transmitter. No user action of any kind nor any contact with the transmitter is required for exchange of a sensor. In this way sensors can be removed and installed between different transmitters at will as may be desired.

- Intelligent installation management: Create and upload complete transmitter configuration to smart digital sensor or download complete transmitter configuration from smart digital sensor to transmitter. Shadow copy feature allows for easy reverting to previous configuration.

- Optimized commissioning & maintenance: Track smart digital sensor initial installation and last used in field dates plus total service time usage. The tracking of this information over the course of time allows for an optimization of stocking levels to further reduce the cost of ownership.

- All aspects of installation are completely portable from the shop to the field.

- Leading novel and proprietary solid-state industrial pH sensor & ORP sensor design and technology combined with built-to-order extensively configurable manufacturing offer the best possible service lifetime at the most cost effective pricepoint. Review the Competitive Advantages of Design & Technology for IOTRON™ & ZEUS™ Industrial pH & ORP Sensors webpage for details.

- 3TX-HiQ intelligent transmitters for smart digital sensors are identical form factor to the 3TX transmitters for analog sensors for seamless integration of both digital & analog sensors & transmitters.

- For measurement with analog Conductivity, Ion Selective (ISE) or Dissolved Oxygen (DO) sensors and shared 3TX module documentation visit the 3TX webpage

- Review the 3TX FAQ before commissioning any system to ensure proper setup & installation.

HiQ Installation Guide with Hook-Up Schematic:

ALTERNATE HiQ Installation Guide with Hook-Up Schematic using Bridge Boxes:

SENSOR CALIBRATION FEATURES & INSTALLATION MANAGEMENT

- Calibration data is stored on smart digital sensor. Calibrate in the lab or instrument shop & snap pre-calibrated sensor into process use. Plug & play sensors can be swapped in and out at will.

- No contact with transmitter of any kind is required for an operator to change out a sensor.

- Calibration values automatically loaded from digital sensor to 3TX-HiQ-pH transmitter.

- Install & swap out for maintenance like cleaning, re-calibration or replacement is quick, easy & simple.

- Rugged field-ready snap connector standard: Smart digital sensors come with 6 meters (20 feet) cable terminated with NEMA 6P & IP67 rated quick disconnect waterproof & corrosion-resistant snap connector. No screwdrivers are ever needed to install or change out a smart digital sensor.

- Total cable length up to 610 meters (2,000 feet) using extension cables with mating rugged NEMA 6P & IP67 quick disconnect waterproof & corrosion-resistant snap connector terminations.

- Automatic pH calibration recognizes 4.00, 6.86, 7.00, 9.18 & 10.00 pH buffers for 1-point, 2-point and 3-point calibrations with built-in correction for temperature induced changes to pH buffers

- See plot of exact pH value of common pH buffers as a function of temperature for visualization of this temperature dependence that is corrected in the 3TX-HiQ-pH automatic calibration mode. Note that this is an altogether different correction than the Nernstian temperature compensation for the pH sensor potential itself. This correction for the value of the pH buffer is a temperature induce equilibrium shift of the measured solution.

- Manual pH calibration allows offset & slope adjustment to any pH buffer or grab sample reference value

- Display previous five calibration sets on transmitter & the date that correspond to each one. Historical & current calibrations can be viewed and saved to track calibrations through sensor lifecycle.

- Total time in field service use is logged on sensor for systematic tracking of complete sensor life cycle to allow for best practice installation, maintenance and inventory/stocking management

- Min and max temperatures in use digitally stamped on sensor for process condition tracking

- Calibrate the smart digital sensor on Windows software as well as on 3TX-HiQ-pH transmitter

- Calibration values can be hard reset back to the ASTI factory defaults (configuration unchanged)

Download the printer friendly two-page version of the pH calibration instructions for the 3TX-HiQ smart digital pH measurement system. Download the printer friendly two-page version of the ORP calibration instructions for the 3TX-HiQ smart digital ORP measurement system. There is also a quick-start guide for 3-point pH buffer calibration in the automatic mode of the 3TX-HiQ-pH transmitter. These printer friendly documents are a selected subset of the complete 3TX-HiQ-pH transmitter documentation which can be downloaded from the link located at the very upper right corner (click on the green 3TX-HiQ-pH faceplate label hotlink).

TRANSMITTER CONFIGURATION MANAGEMENT FEATURES

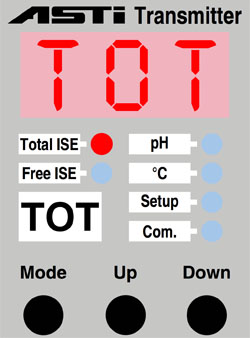

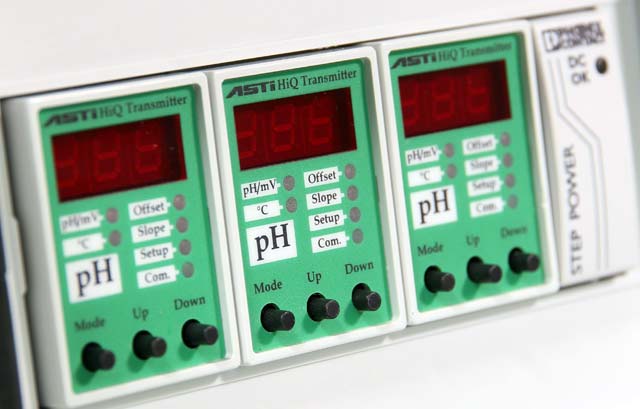

3TX-4MW-3EA-HiQ-pH-PS Triple Channel Intelligent Digital Transmitter Assembly

Female snap panel connectors for smart digital male HiQ4M snap connector sensor input

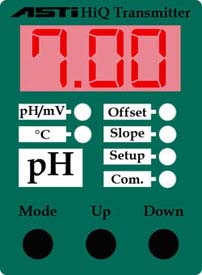

Detail view of 3TX-HiQ-pH Intelligent Digital pH/ORP transmitters.

All functionality is accomplished by means of the ‘Mode’, ‘Up’ or ‘Down’ buttons.

- The HiQ configuration system features are available by pairing the smart digital HiQ sensor with the intelligent 3TX-HiQ transmitter, selecting the desired parameter settings and saving this configuration to a Windows file or else invoking a shadow copy on the 3TX-HiQ transmitter.

- The HiQ configuration system provides systematic & advanced management of the your field installations without the high cost and complexity of the HART®, Profibus or FOUNDATION™ fieldbus digital protocols.

- The HiQ configuration system allows for very detailed tracking of both the current and previous complete transmitter configuration for each installation point in a simple and low-cost manner.

- Transmitter configuration on 3TX-HiQ can be downloaded to the smart digital sensor as a backup or else to be uploaded directly onto other 3TX-HiQ transmitters to clone configurations

- Configuration on the smart digital sensor can be saved as a file when used with the supplied Windows software for backup, archiving or tracking the configurations at each installation site

- Configurations saved to file can be directly loaded to smart digital sensor. Configurations loaded to sensor can in turn be loaded onto any 3TX-HiQ transmitter to which it is connected.

- The 3TX-HiQ transmitter can create a restore point backup of the exact current working configuration. The 3TX-HiQ can be reverted back to this restore point configuration at any time.

- The 3TX-HiQ transmitter configuration can be hard reset back to the ASTI factory defaults

OVERALL 3TX-HiQ-pH MEASUREMENT SYSTEM FUNCTIONALITY

- One pH/ORP transmitter for all your needs: -2 to +16 pH range services all possible pH installs. The -1,000 to +1,000 mV ORP range services nearly all possible practical field ORP applications.

- Analog 0-20mA or 4-20mA output can be scaled to 1pH to get an effective output resolution of 0.001pH units or else down to 100mV to get a net output resolution of 0.1mV for any part of the ORP range.

- The RS-485 MODbus RTU output mode can be set to achieve a 0.001pH or 0.1mV resolution for best precision or set to a lower 0.01pH and 1mV resolution mode to achieve compatibility with the 3TX-DAT MODbus field datalogger or else if the higher resolution mode is simply not desired

- 3TX-HiQ-pH transmitter comes standard with both scalable analog 0-20mA or 4-20mA to support legacy control systems & RS-485 MODBUS for use with more modern digital control systems.

- Commissioning new field installations using RS-485 MODBUS RTU digital output is as simple as daisy-chain wiring together all installed 3TX-HiQ transmitters and assigning the node address for each module.

- The MODBUS protocol allows for the flexibility to add or remove nodes at will and avoid any potential ground loops issues.

- Analog output is galvanically isolated from the sensor input, scalable linear and fully reversible.

- User adjustable temperature compensation coefficient for special sensors & critical applications.

- Automatic temperature compensation (ATC) from -40 to +210°C ensures accurate pH readings.

- Analog and digital outputs are placed on hold automatically when in calibration mode. When calibration mode is entered, the last value from measurement mode will be held for both the 4-20mA analog output as well as the MODbus output.

- Active 4-20mA can support remote external displays to allow for viewing measured values in control panels, secondary field locations, or instrumentation shops.

- An example of how to connect a single 4-20mA output to multiple devices is provided in this drawing

- Although all of the 3TX transmitters are 3-wire devices they can be powered with installations that are designed for 2-wire loop-powered devices by using the following 2-wire to 3-wire installation scheme. Please review the 3TX FAQ for the typical 3-wire power and output installation scheme for the 3TX modules.

SMART DIGITAL SENSORS FOR USE WITH 3TX-HiQ-pH INTELLIGENT DIGITAL TRANSMITTER

Selected smart digital pH sensors with low-profile thick-wall break-resistant parabolic pH glass elements for use in slurry process solutions

- Entire line of proven built-to-order customizable application specific Iotron™ inline, immersion, submersible, twist lock, sanitary, HOT-TAP retractable pH & ORP sensors can be viewed from the pH Sensors & ORP sensors overview webpage. ALL of these sensors are available in configurations that are suitable for use with 3TX-HiQ-pH transmitter.

- Ultra-Rugged Industrial Grade Construction ZEUS™ SMART DIGITAL pH SENSORS and ZEUS™ SMART DIGITAL ORP SENSORS are an ideal choice for use in Tough Process Inline, Immersion or Submersible installations suitable for measurements with High Temperatures & High Pressures, Dissolved Ammonia, Chorine, Sulfides & Solvents and many other aggressive conditions. The relevant dimensional detail drawing is extracted below for visualization purposes.

- The ZEUS™ SMART DIGITAL pH SENSORS & ORP SENSORS are typically in stock or available on a short lead time to solve your most difficult and severe service pH measurement application promptly.

- The complete specification sheet and installation guide can be downloaded for the Item # 1205 ZEUS™ SMART DIGITAL pH SENSOR and Item # 1234 ZEUS™ SMART DIGITAL ORP SENSOR or else can be obtained from the QR code on the ZEUS™ sensor label via the QR scanner app on your mobile device.

- Additional information about the ZEUS™ SMART DIGITAL pH SENSORS can be found on the main ZEUS™ pH sensors webpage

- The unique rugged low-profile impact & break resistant parabolic pH glass element optimized for use in slurries & high viscosity applications (X3XX series) is available as a smart digital sensor

- The novel extreme dehydration resistant style reference technology that allows for prolonged exposure to dry conditions and intermittent wet & dry use also available as smart digital sensor

Dimensional Drawing for ZEUS™ Smart Digital pH Sensors for Inline, Immersion & Submersion

Industrial Process Installations for use with 3TX-HiQ-pH Intelligent Digital Transmitter

Complete assembly showing smart digital dual pH/ORP all-in-one sensor with HiQ7M snap connector interfaced to HiQ7F female snap to tinned lead extension cable which is terminated to two (2) each 3TX-HiQ-pH transmitters. One of the modules displays and outputs the pH while the other module displays and outputs ORP from the connected smart digital dual pH/ORP all-in-one sensor.

The twist lock quick disconnect bayonet style configuration of the smart digital dual pH/ORP all-in-one sensor is shown interfaced with the 1”MNPT PEEK twist lock receptacle and terminated with the HiQ7M male snap connector. The configuration allows for a single installation point to measure pH, ORP and temperature values simultaneously for simplicity of commissioning as well as ease of stocking just a single sensor for multiple measurements. In cases where more expensive installation hardware is required such as for HOT-TAP valve retractable and sanitary type installations this dual pH/ORP smart digital sensor configuration can also significantly reduce the commissioning cost associated with measuring both the pH & ORP process values.

Installation guide for smart digital dual pH/ORP all-in-one sensor configuration for use with 3TX-HiQ-pH intelligent pH/ORP transmitters

WHAT ARE THE BENEFITS OF USING IOTRON™ SMART DIGITAL SENSORS?

- 100% pure digital communications means reliable operation even in noisy process environments.

- No degradation in signal even with very long cable runs up to max of 610 meters (2,000 feet)

- Bridging connections & modifying installations is easy and done without loss of signal quality with NEMA 6P & IP67 quick disconnect waterproof and corrosion-resistant snap connectors.

- Low-cost snap digital extension cables facilitate consolidation of transmitters into a single panel enclosure where very many remote field installations can all be conveniently all viewed at once.

- Smart 3TX-HiQ software identifies the type of sensor connected to confirm it is compatible for the mating transmitter. There exists no possibility of ever interfacing the wrong sensor type.

- 3TX-HiQ-pH smart configuration feature automatically recognizes & differentiates between pH & ORP sensors. The relevant settings are automatically adjusted if existing setup is incompatible.

- Input terminal wiring identical for all smart digital 3TX-HiQ measurement modules. Smart sensors have exactly the same color coding & wiring to input terminals on 3TX-HiQ transmitters.

- All Extension cables for HiQ sensors are intercompatible. Uniform extension cables minimize stocking. Field installation guide details options to commission & exchange sensors in the field.

SENSOR & INSTALLATION TRACKING FEATURES

- Digital date stamping of dispatch from factory, initial field installation & final field service use

- Digital stamping of serial number & item number for each smart digital HiQ style sensor

SELECTED PHOTO OF TURN-KEY PLUG & PLAY SMART DIGITAL pH MEASUREMENT & DATALOGGING SYSTEMS

IOTRON™ Smart Digital pH Sensor & 3TX-HiQ-pH Intelligent Digital pH Transmitter with MODBUS 3TX-DAT Field Datalogger with quick disconnect snap RS-232 to USB download cable

3MF NEMA 4X Rated Enclosure complete with 2 each HiQ4FP panel snap connectors for HiQ4M inputs

3TX-3MF-2H-HiQ-pH-DAT-PS ready for wall/plate installation or 2″ NPT pipe mounting with optional kit

PNXGR 8052-HiQ IOTRON™ Smart Digital Twist Lock Quick Disconnect Bayonet Style Inline pH Sensor with HiQ4M snap connector

3TX-2M-1H-HiQ-pH-PS Intelligent Digital Transmitter with HiQ4FP panel mount connectors for HiQ4M snap input

Datalogging on Windows PC using RS-485 to USB converter from MODBUS RTU from 3TX-HiQ-pH (100 feet twisted-pair cable shown)

IP65 Rated Enclosure complete with universal 100-240 VAC line powered operation ready for immediate commissioning

3TX-2M-1H-HiQ-pH-PS ready for wall/plate installation or 2″ NPT pipe mounting with optional kit

Plug & Play Submersible pH & ORP Measurement System for Intermittent Battery-Powered Operation at Remote Installations detailed as Case Study # 22

PNXGRE 5631/5331-HiQ-12m-WPB/20 IOTRON™ Smart Digital Submersible pH Sensor for Intermittent Wet & Dry Use & Hot-Swap Exchange

3TX-7MF-3H-2EA-HiQ-pH-DAT-Q2FP-UPT Intelligent Digital pH & ORP Measurement & Datalogging System for Smart Digital pH/ORP Sensors

Ultralow-Power-Timer (UPT) switch uses just 0.4mA @ 24VDC to allow for very long intermittent operation from Sealed Lead Acid (SLA) Batteries

Logged pH, ORP & temperature data is downloaded & visualized on Windows PC via RS-232 to USB snap plug & play cable to 3TX-DAT Datalogger

NEMA 4X Rated Field Enclosure System with all NEMA 6P rated snap connections is ready for immediate commissioning

7MF-24VDC-2EA-12AH-SLA-Q2FP Hot-Swappable 24VDC battery power supply with Q2M-Xm-Q2M snap disconnect power cable & 3TX-7MF-3H-2EA-HiQ-pH-DAT-Q2FP-UPT Measurement & Datalogging System Ready for wall/plate installation or 2″ NPT pipe mounting with optional kit

SELECTED PHOTOS OF IOTRON™ SMART DIGITAL SENSORS

5X31 Sanitary Series smart digital pH sensor with “GR” protective tines and WPIT sealing option

PNXGR 8052-HiQ Twist Lock Series smart digital pH sensor with “GR” 4 each protective tines

Standard grommet seal provided for all sensors if no waterproofing option is invoked

For outdoor use or else indoor use with wet environments and/or washdowns as well as

Fully submersible installations without an immersion rod see the waterproofing options

Detail view of HiQ4F female snap connector & HiQ4M male snap connector for digital sensors

Snap to Snap extension cable for smart digital HiQ sensors

6X31 series submersible pH sensor with WPH sealing option

PNGRO 6011-HiQ 3/4″-3/4″ Inline/Immersion smart digital pH sensor with “GRO” 2 each protective tines

PNTJ 6831/6631-HiQ Sulfide Resistant Smart Digital ORP Sensor for Inline & Immersion Use

PN 6053-HiQ General Purpose Smart Digital pH Sensor for Inline & Immersion Use

Close-up detail view of “stubby” sensor cable assembly shown without mating snap extension cable. This “stubby” option is available for all sensors with 1”MNPT or larger rear threads.

“Stubby” style sensor assembly option allows for minimal cable length for ease of commissioning and swap-out in the field with very robust NEMA 6P rated waterproof connector system.

WINDOWS SOFTWARE FOR CALIBRATION & CONFIGURATION OF SMART DIGITAL pH SENSORS & ORP SENSORS FOR 3TX-HiQ-pH TRANSMITTERS

HiQ to Windows Bridge Box Assembly with Portability Package Option (Item # 14099) with

ZEUS™ pH sensor in Smart Digital Configuration (Item # 1205) & USB Male “A” to Q6M cable

Ready for use as a field calibrator of smart digital sensors with Windows PC or tablet.

Portable HiQ to Windows Bridge Box Close-Up detailing industrial RS-485 to USB converter.

Top angle view showing rugged carrying handle & rubber feet installed for ease of portability.

Sealing caps ensure NEMA4X rating when sensor input and USB output ports are not in use.

- Download the Manual for the Windows software for calibration of HiQ smart digital sensors and setup of configurations for 3TX-HiQ intelligent transmitters.

- HiQ Windows software is provided with a free of charge perpetual software zero cost license. Only a suitable RS-485 to USB converter assembly is required to use the Windows software. ASTI offers a field ready NEMA4X Windows Interface Bridge Box for Smart Digital HiQ Sensors to enable turn-key out of the box use of this HiQ Windows software.

- HiQ Windows software provides convenient testing and calibration of plug and play smart digital sensor as well as creating complete 3TX-HiQ transmitter configuration which can be saved to file as well as to additional HiQ smart digital sensors. This can be done for various field installation points throughout the plant from anywhere that a laptop, desktop or tablet with a USB connection is available.

- Windows software is not required for any feature of the 3TX-HiQ intelligent transmitter and smart digital sensor measurement platform but rather available for those that prefer to calibrate the sensor and configure the transmitter with this option.

- Calibrate the smart digital sensors:

- All sensors can be offset calibrated for temperature.

- The HiQ smart digital pH sensors can accept 1-point (offset), 2-point (slope) as well as a 3-point calibration that results in a dual slope scheme whereby you can a separate operating slope for acidic and alkaline measurement ranges.

- The pH calibrations can be done using the autoread algorithm to ensure systematic results no matter which operator performs the pH sensor calibration.

- The ORP sensor can be offset for the mV reading to create a calibrated relative mV (RmV) value for use as a process control setpoint.

- The complete sensor status can be viewed. The stats window allows for following information:

- Permanent values such as the sensor item number (this also serves as the reorder code and complete sensor model assignment), invoice number & dispatch date from ASTI factory, sensor serial number, sensor type, sensor board software revision and first installation date in field (activation).

- Dynamic information can be obtained to give a “snapshot” of the current sensor status such as the last five calibration values for temperature, offset and slope(s) as well as the last date used, the total actual time the sensor has been used in field service as well as the highest and lowest temperature values experienced in process.

- HiQ Windows software functions as a pH measurement and ORP measurement device even if no 3TX-HiQ-pH transmitter is present. This means that the Windows software is capable to function as an equivalent to a laboratory pH meter or ORP meter displaying the calibrated pH, relative mV (ORP) and temperature values from the connected digital HiQ sensor.

- If you wish to record the values obtained from your measurements in a laboratory or field shop type setting then please use the MODBUS output from 3TX-HiQ-pH in conjunction with the free of charge ASTI Windows datalogging and graphing software for 3TX transmitters with MODBUS output (see below for further details on this separate software package)

TYPICAL FIELD COMMISSIONING SCHEME FOR HiQ SMART DIGITAL MEASUREMENT SYSTEMS

HiQ to Windows Bridge Box Assembly with Portability Package Option (Item # 14099) with

ZEUS™ pH sensor in Smart Digital Configuration (Item # 1205) & USB Male “A” to Q6M cable

Ready for use as a field calibrator of smart digital sensors with Windows PC or tablet.

Portable HiQ to Windows Bridge Box Close-Up detailing industrial RS-485 to USB converter.

Top angle view showing rugged carrying handle & rubber feet installed for ease of portability.

Sealing caps ensure NEMA4X rating when sensor input and USB output ports are not in use.

- Download the Manual for the Windows software for calibration of HiQ smart digital sensors and setup of configurations for 3TX-HiQ intelligent transmitters. The installer for this software can be requested here.

- HiQ Windows software is provided with a free of charge perpetual software zero cost license. Only a suitable RS-485 to USB converter assembly is required to use the Windows software. ASTI offers a field ready NEMA4X Windows Interface Bridge Box for Smart Digital HiQ Sensors to enable turn-key out of the box use of this HiQ Windows software.

- HiQ Windows software provides convenient testing and calibration of plug and play smart digital sensor as well as creating complete 3TX-HiQ transmitter configuration which can be saved to file as well as to additional HiQ smart digital sensors. This can be done for various field installation points throughout the plant from anywhere that a laptop, desktop or tablet with a USB connection is available.

- Windows software is not required for any feature of the 3TX-HiQ intelligent transmitter and smart digital sensor measurement platform but rather available for those that prefer to calibrate the sensor and configure the transmitter with this option.

- Calibrate the smart digital sensors:

- All sensors can be offset calibrated for temperature.

- The HiQ smart digital pH sensors can accept 1-point (offset), 2-point (slope) as well as a 3-point calibration that results in a dual slope scheme whereby you can a separate operating slope for acidic and alkaline measurement ranges.

- The pH calibrations can be done using the autoread algorithm to ensure systematic results no matter which operator performs the pH sensor calibration.

- The ORP sensor can be offset for the mV reading to create a calibrated relative mV (RmV) value for use as a process control setpoint.

- The complete sensor status can be viewed. The stats window allows for following information:

- Permanent values such as the sensor item number (this also serves as the reorder code and complete sensor model assignment), invoice number & dispatch date from ASTI factory, sensor serial number, sensor type, sensor board software revision and first installation date in field (activation).

- Dynamic information can be obtained to give a “snapshot” of the current sensor status such as the last five calibration values for temperature, offset and slope(s) as well as the last date used, the total actual time the sensor has been used in field service as well as the highest and lowest temperature values experienced in process.

- HiQ Windows software functions as a pH measurement and ORP measurement device even if no 3TX-HiQ-pH transmitter is present. This means that the Windows software is capable to function as an equivalent to a laboratory pH meter or ORP meter displaying the calibrated pH, relative mV (ORP) and temperature values from the connected digital HiQ sensor.

- If you wish to record the values obtained from your measurements in a laboratory or field shop type setting then please use the MODBUS output from 3TX-HiQ-pH in conjunction with the free of charge ASTI Windows datalogging and graphing software for 3TX transmitters with MODBUS output (see below for further details on this separate software package)

TYPICAL FIELD COMMISSIONING SCHEME FOR HiQ SMART DIGITAL MEAUSREMENT SYSTEMS

“LUNCHBOX” portable assembly with 6700mAH rated LiPo battery & Smart Digital ZEUS™ pH sensor interfaced via HiQ4FP female panel connector to mate with HiQ4M male sensor snap connector

Ready for use as a field calibrator of smart digital pH/ORP sensors for 3TX-HiQ digital transmitters or intermittent and spot grab sample measurements in process media in configuration shown above.

Install protective caps when any port is not in use to ensure NEMA 4X rating of assembly.

Side angle view showing rugged carrying handle & rubber feet installed for ease of portability.

Measuring 3TX module installed can be swapped as desired from 35mm DIN-RAIL hardware.

Protective caps are supplied to seal all ports not actively in use to maintain NEMA 4X rating.

3350mAH @ 5VDC rated lithium polymer (LiPo) battery shown installed for ~4.5 hours runtime.

Optional larger 6700mAH @ 5VDC LiPo battery pack (shown to left) will allow ~9 hours runtime.

- Calibrate smart digital HiQ sensor with Windows software or spare 3TX-HiQ transmitter. If using the Windows software this requires that the ASTI supplied HiQ to Windows bridge box has been previously purchased either as a part of the original commissioning package or with a subsequent order. The HiQ to Windows bridge box is NOT included with the main HiQ digital measurement system package since it is optional rather than a required equipment.

- The values from the calibrations performed with the Windows software will not be written to the calibration history for a brand new out of box HiQ digital sensor but can be viewed in the calibrate Window.

- Calibration values will only be written to the history after the sensor is field activated (see below).If you wish to simply test the functionality of your new-in-box smart digital 3TX-HIQ sensor without setting the initial field installation date only the Windows software can allow you accomplish this goal.

- The initial calibration and transmitter configuration can also be performed directly between the 3TX-HiQ intelligent digital transmitter and smart digital HiQ sensor instead of using the Windows software. Beyond ease of accomplishing this initial calibration and configuration, the main difference is that the initial field installation date (activation) will be date stamped if this initial calibration and configuration is done with the 3TX-HIQ transmitter. If initial calibration and configuration is done with the Windows software, then this initial field installation date will not be stamped. The first calibration will also not be written to the calibration history but can still be viewed from the 3TX-HIQ transmitter as a display feature as well as the Windows software itself in the calibrate mode.

- The values from the calibrations performed with the Windows software will not be written to the calibration history for a brand new out of box HiQ digital sensor but can be viewed in the calibrate Window.

- Setup the 3TX-HiQ transmitter configuration as is desired for the planned installation point with the Windows software or spare 3TX-HiQ transmitter. Using the Windows software to create the configuration allows for it to be saved on the PC with a logical filename should it need to be loaded onto a new sensor in the future or else to keep track of changes to the transmitter configuration over time for the given installation point. If multiple installations will use exactly the same transmitter configuration this same file can be loaded onto multiple sensors. This task of loading the same configuration onto multiple smart digital sensors can also be accomplished via the 3TX-HiQ Intelligent transmitter using the appropriate parameter call.

- Connect the HiQ smart digital sensor that was previously calibrated with the Windows software to the 3TX-HiQ transmitter. The calibration values will be automatically loaded and the values displayed in the measurement mode will reflect the process parameter and temperature including this previous calibration done with the Windows software. At this moment the initial installation field is stamped onto the sensor as the activation date. After this moment, the last date in field service will also be stamped whenever this sensor is connected to any intelligent HiQ digital transmitter.

- Load the configuration saved onto the smart digital HiQ sensor onto the 3TX-HiQ transmitter (see transmitter manual for details on this step).

- All calibrations performed with the 3TX-HiQ-pH transmitter or the HiQ Windows software will be recorded in the calibration history after the sensor has been activated. It is not relevant whether subsequent calibrations are performed with the same 3TX-HiQ-pH transmitter at the field installation site or else a separate line-powered 3TX-HiQ-pH transmitter in the shop or else as part of a portable battery-powered LUNCHBOX or CARRY-ON assembly. Either way the calibration will be saved and written to the calibration history.

TYPICAL OPTIMIZED ONGOING MAINTENANCE SCHEME & WORKFLOW FOR HiQ SMART DIGITAL MEAUSREMENT SYSTEMS

- One of the core advantages of the smart digital HiQ platform is the availability to calibrate in one location and to install the sensor into another location. The calibration values saved on the sensor are automatically loaded to the 3TX-HiQ intelligent transmitter after the sensor is interfaced with the NEMA 6P rated field snap connector without any user action of any kind meaning for a true plug and play hot-swap ability between any sensor and transmitter.

- The choice of where to perform the calibration is a matter of what is best for your particular facility and operational setup. In order to avoid downtime while the calibrations are performed, at least one spare HiQ digital sensor is required. If a spare HiQ sensor was not purchased as a part of the initial commissioning it is recommended to purchase one for ongoing maintenance best practice.

- There are three convenient options to perform the calibration of the HiQ digital sensor and modify the transmitter configuration after the initial field commissioning aside from using the field installed 3TX-HiQ transmitter to which the HiQ sensor is installed for continuous inline service. All are functionally equivalent and the choice of which approach is employed need only be selected based upon what best suits your needs. The three possibilities are:

- Use a spare 3TX-HiQ transmitter assembly. The unit employed can be identical to the field commissioned package so that this spare 3TX-HiQ transmitter assembly can serve both for purposes of calibration as well as a backup in case the field unit(s) are damaged due to some unforeseen incident.

- Use a portable LUNCHBOX or CARRYON assembly with a 3TX-HiQ transmitter installed. The primary advantage here is that such a portable unit is battery powered (either from a 9V or a 5V USB rechargeable cell) and so the calibration can be done in any location whether line power is available or not. This portable assembly can also serve to spot check process measurement values as well as performing recalibration for the field installed sensors.

- Use the HiQ Windows software. This can be done in the lab with a desktop PC and also in the field if the HiQ to Windows bridge box is purchased with the portability package and a laptop computer is employed.

- Note that when calibrating a sensor new out of box only the Windows software will not stamp the sensor with the initial installation field activation date nor the last date in service.

- If you simply wish to spot-check any sensor in stock then the Windows approach is the best choice as it will not stamp/update either the field activation (first date in use) nor the last date field in field service dates.

- While calibration values from any of the three choices detailed above will automatically be loaded onto the field installed inline 3TX-HiQ transmitter in contrast any change in the transmitter configuration requires an affirmative user action (see 3TX-HiQ or HiQ Windows manual for more details about this aspect). This requirement for an affirmative user action to make any change to the transmitter configuration is done to prevent accidental crossing of transmitter configuration for different installation points.

- Since transmitter configurations are NOT automatically loaded from the HiQ sensors (but rather only the calibration are automatically loaded) this design scheme allows for the HiQ sensors to be seamlessly hot-swapped between installations that may have different transmitter configuration but use the same sensor model.

- It is best practice to save any modifications to the transmitter configuration for a given installation point as a new filename from the HiQ Windows software for archival tracking of transmitter configurations as well as to allowing to revert to a previous setup if desired.

Download the printer friendly two-page version of the best practice initial commissioning & ongoing maintenance scheme for the 3TX-HiQ smart digital pH & ORP measurement system as detailed in the paragraphs above. This printer friendly document is a selected subset of the larger printer friendly PDF document containing all information on this entire webpage which can be downloaded from the link located at the very upper right corner.

The modular components of the 3TX series provide the flexibility to meet your application needs in a cost-effective way:

- Custom configurations offer the freedom to only pay for the specific modules you need

- Select any combination of measurements that you need: pH, ORP, dissolved oxygen (DO), conductivity, ion selective (ISE) and temperature. The pH and ORP measurement can be accomplished either via digital or analog sensors. The ion selective (ISE), dissolved oxygen (DO) and conductivity measurements must be accomplished by means of an analog sensor.

- Select the number of measurement channels in the field assembly, from a single channel up to nine (9) channels

- Enjoy the flexibility to add measurement and/or complementary modulesafter commissioning using the original analyzer assembly (assuming sufficient room exists for the expansion in the selected enclosure).

- Measurement modules can be added for inline measurement of the pH/ORP parameters using the 3TX-pH for analog sensors and the 3TX-HiQ-pH for digital sensors

- Measurement modules can be added for inline measurement of ion selective (3TX-ISE), dissolved oxygen (3TX-DO) and conductivity (3TX-CON) parameters for use with analog sensors.

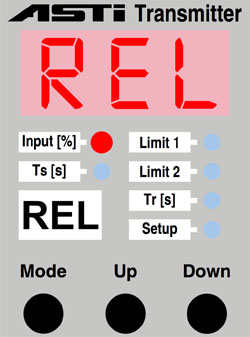

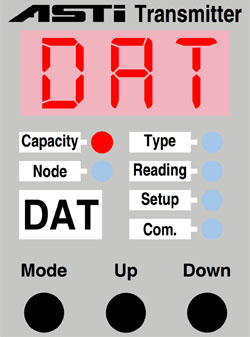

- In addition the 3TX-HiQ intelligent digital transmitters can be interfaced with complementary modules such as programmable alarm/relay controllers (3TX-REL), MODBUS dataloggers (3TX-DAT) and pH compensation for ISE modules including MODbus converter for all inputs (3TX-TOT).

All modules in the 3TX series share these features and options:

- Easy-to-read displays: Bright three-digit LED displays are visible even in bright sunlight and do not suffer from the common problems associated with LCD displays, such as environmental fatigue and wear.

- Easy to use: Simple and intuitive three-button operation with no complex codes to memorize for most day-to-day tasks.

- Easy installation: Enclosures are customized for your modules and arrive ready for field mounting on any wall with no additional specialized hardware required. Modules are also available individually in a small, 35mm DIN-rail mountable form factor for direct integration into OEM equipment.

- Galvanic isolation between all inputs, power & analog output (3000V rating)

- Weatherproof: NEMA 4X CSA/UL rated & IP65 enclosures include high quality sealing cable glands (a.k.a. strain relief) that are ideal for weatherproof sealing on sensor, power, and output cables. Waterproof caps are also provided at no additional cost for all cable glands to seal and weatherproof any channels that will not be used.

- Certifications: CE marked for use in safe, non-hazardous areas (Class I, Division II or above – a.k.a. Zone 1 or above).

- Security: Optional lock available for enclosure assembly to restrict access to selected keyholders.

- Power supply options: Choose our CSA/UL/CE approved universal 100 to 240 VAC 50/60 Hz power supply module for line powered operation, or you may use any module with a 3-wire 24VDC powered operation if you already have a dedicated 24VDC power supply (i.e. not shared with other equipment) available onsite.

- Battery powered options: Portable 3TX Transmitter Assemblies are field ready for Temporary Installations, Troubleshooting and Grab Sample Analysis of pH, OPP, Ion Selective (ISE), Conductivity & Dissolved Oxygen (DO) parameters of process samples using industrial analog and digital sensors. The 3TX portable assemblies employ the 3TX-PS/BAT module that provides dual isolated and regulated 24VDC power to energize the 3TX transmitters from 5V, 6V or 9V rechargeable or non-rechargeable battery sources. Portable assemblies can be converted to permanent continuous inline measurement systems for ease of going from proof of feasibility to closed-loop control.

- The 3TX portable assemblies are an ideal choice for applications where power is either unstable/unreliable or else when no AC or DC power source is available at all. All portable 3TX assemblies can be converted for use as permanent installations since the enclosure and all employed fittings are NEMA4X rated.

- Option to customize default values for 3TX transmitters for use with analog sensors: Each module can be preset with your own preferred defaults for all user parameters at no additional cost (minimum order quantities may apply). This allows for your own customized transmitter configuration to be restored in the field using the reset all parameters function that is implemented on all 3TX modules.

- 1/2-DIN Panel & Pipe mounting option: A universal two-inch (2”) NPT pipe mounting kit is available for all 3TX enclosure options. The 3MP enclosure can be installed into any standard ½-DIN panel cutout. All enclosures are ready for wall mounting standard without any additional special hardware.

- Factory Statement of Warranty for 3TX Transmitters: Please review before making any purchase and inquire to factory with questions if necessary.

Download the dimensional drawings for the weatherproof 2M, 4M & 6M IP65 enclosures and pipe mounting kit

Download the dimensional drawings for the NEMA 4X CSA/UL listed 3MP 1/2-DIN panel mounting enclosure assembly

Download the dimensional drawings for the NEMA 4X CSA/UL listed 3MF field wall & pipe mounting enclosure assembly

Download the dimensional drawings for the NEMA 4X CSA/UL listed 5MF field wall & pipe mounting enclosure assembly

Download the dimensional drawings for the NEMA 4X CSA/UL listed 7MF field wall & pipe mounting enclosure assembly

Control Module (3TX-REL)

- Each 3TX-REL module has 2 each independent Single-Pole Single-Throw (SPST) 5 Amp contact relays.

- Each relay is fully configurable by the user as to control mode and variables for each control algorithm.

- Tight integration between 3TX alarm & relay controller and 3TX measurement modules software makes configuration and scaling simple & easy for any local control requirements of the pH, ORP, ion selective (ISE), dissolved oxygen (DO) or conductivity parameters. Find below a very useful configuration guide for setup of the REL module with any of the 3TX measurement modules:

- The 3TX-REL alarm and relay controller module includes both basic and more sophisticated controlling options, including all of the following modes:

- 1) A simple supervision option for alarm functionality only;

- 2) An On/Off control with a user-configurable deadband (a.k.a. hysteresis);

- 3) Time proportional control (TPC); and,

- 4) Proportional frequency control (PFC, a.k.a. variable pulse controller).

Download the alternate wiring schematic for 3TX-REL module when analog 0/4-20mA output from 3TX-HiQ-pH, 3TX-pH, 3TX-ISE, 3TX-DO or 3TX-CON measurement transmitter is to be connected to other data acquisition or control device prior to connection with 3TX-REL alarm/relay module. Standard wiring for when the analog output from measurement transmitter is connected directly to the 3TX-REL is contained in the respective measurement module specification sheet.

Datalogging Options for MODbus output from 3TX-HiQ Digital Transmitters

- 1) You may use a free of charge optional Windows PC software interface kit to the MODbus digital output. This allows for real time display of all values for all transmitters that are wired to that MODbus line. In addition, the software kit allows for datalogging for all transmitters connected on the line, including both the scaled output value and temperature for each measurement module. Up to 247 devices can be supported on a single MODbus digital line (2-wire cable), and long cable length can be supported for field installations up to 6500 feet (1.23 miles or 1.98 kilometers) to make viewing in the instrument shop practical and easy.

- Find below a link to the installation and user manual for the free of charge Windows PC datalogging and graphing software described above for use with 3TX transmitters with the optional MODbus RS-485 digital output (Revision 2.5):

- 2) Alternatively, you may add a 3TX-DAT field datalogging module. The 3TX-DAT module allows for datalogging of up to 63 each MODbus digital inputs from any mix of digital 3TX-HiQ and analog 3TX-pH, 3TX-ISE, 3TX-CON, 3TX-DO and 3TX-TOT modules as input nodes . The sampling rate is fully configurable from once per second to once per hour, although all nodes must have the same sampling rate. With 8MB onboard flash memory standard there is a quite extensive datalogging capacity. Configuration of the 3TX-DAT is accomplished via the free of charge Windows datalogging and graphing software for 3TX transmitters with MODbus and uploaded & downloaded using the separate Windows software for 3TX-DAT. The 3TX-DAT unit can be supplied pre-configured from the ASTI factory upon request without additional charge. The logged data is downloaded to a PC or tablet for further workup, with graphing and analysis also via the Windows software. The 3TX-DAT can be added at any time after commissioning if datalogging should become a requirement provided that the mating measurement module(s) have the MODbus output option and sufficient room has been left in the ASTI supplied or customer provided enclosure assembly.

- Find below a link to the installation and user manual for the free of charge Windows PC DAT Configuration & Download software described above for use with 3TX transmitters with the optional MODbus RS-485 digital output together with the DAT logging module (Revision 1.5):

3TX-TOT pH Compensation Module to Compute Total ISE

- The 3TX-TOT module computes the total ISE. For example, this module can compute total ammonia, total fluoride and total cyanide.

- The module computes the total ISE using three inputs: 1) the free ion activity; 2) the pH; and, 3) the temperature. These three input parameters are provided by the analog output from the respective measurement modules.

- A scalable 4-20mA analog signal is available to output the computed total ISE to PLC or other data acquisition equipment.

- MODbus output is standard: All input and output data can be sent via RS-485 MODbus RTU from the 3TX-TOT module.

- The following links provide examples for visualization of some common weak base and weak acid species where the total ISE can be determined:

- Total Ammonia (NH3-N, or total ammonia as nitrogen)

- Total Fluoride (Total HF, or unreacted fluoride)

- Total Cyanide (Total HCN, or unreacted cyanide)

- Additional pH compensation algorithms for other weak acid and weak base species can be readily added upon request as special orders (MOQ may apply).

- Find below a link to the technical document that summarizes the capabilities of the 3TX-TOT module and addresses the questions of what exactly pH compensation means for ISE measurements and when it is required (recommended):

- Find below a link for the 3TX-TOT wiring supplement for the Approach 1 Spliced Pt100/Pt1000 TC input scheme when using pH & ISE sensors with integral preamplifiers:

- Download the MODbus output summary supplement for the 3TX-TOT to assist with configuration of your MODbus data acquisition, SCADA or control system.

Selected Complementary Mating Modules for Control & Datalogging of pH & ORP Measurement with 3TX-HiQ-pH Digital Transmitters

| Measurement | Input | Measurement Range | Outputs | Calibration Capabilities | Special HiQ Smart Digital Sensor Features | Special HiQ Intelligent Transmitter Features |

| pH or ORP3TX-HiQ-pH | – Any Iotron™ Series Smart Digital pH Sensor or ORP Sensor- ZEUS™ pH Sensor in Smart Digital Configuration, Item # 1205 | -2 to +16 for pH Mode -1000 to +1000 mV for ORP Mode | – Fully Isolated, Scalable & Reversible Analog 0-20 mA or 4-20 mA output for pH or ORP process value- Minimum 1 pH unit or 100mV for ORP mode between 0/4mA and 20mA output setpoints- RS-485 MODbus digital output comes standard; High Resolution mode or 3TX-DAT compatible mode | – 2 point or 3 point calibration for determination of acid and alkaline slopes – 1 point user defined pH standardize calibration to correct for offset (drift)- Offset calibration for temperature value | – Date stamping for initial installation (field activation), last date in field service and total time in use allows for detailed life-cycle management for optimal inventory.- Date stamping for dispatch from factory, factory invoice number as well as sensor item number & serial number for detailed procurement tracking.- Entire 3TX-HiQ-pH intelligent transmitter configuration can be saved on the smart digital pH sensor or ORP sensor for cloning of setup or else as a backup to enable reverting capability. | – Calibration values from connected HiQ-pH or HiQ-ORP sensor are automatically loaded without any user action. Last 5 calibrations stored on sensor can be viewed.- Shadow copy of configuration allows for on-the-fly saving of current configuration with ability to later revert back if desired.- Entire transmitter configuration can be loaded onto connected smart digital HiQ smart digital pH or ORP sensor for cloning to other transmitter(s) or else for saving to file with Windows software for archival purposes. |