HiQDT Smart Digital Modbus Measurement System

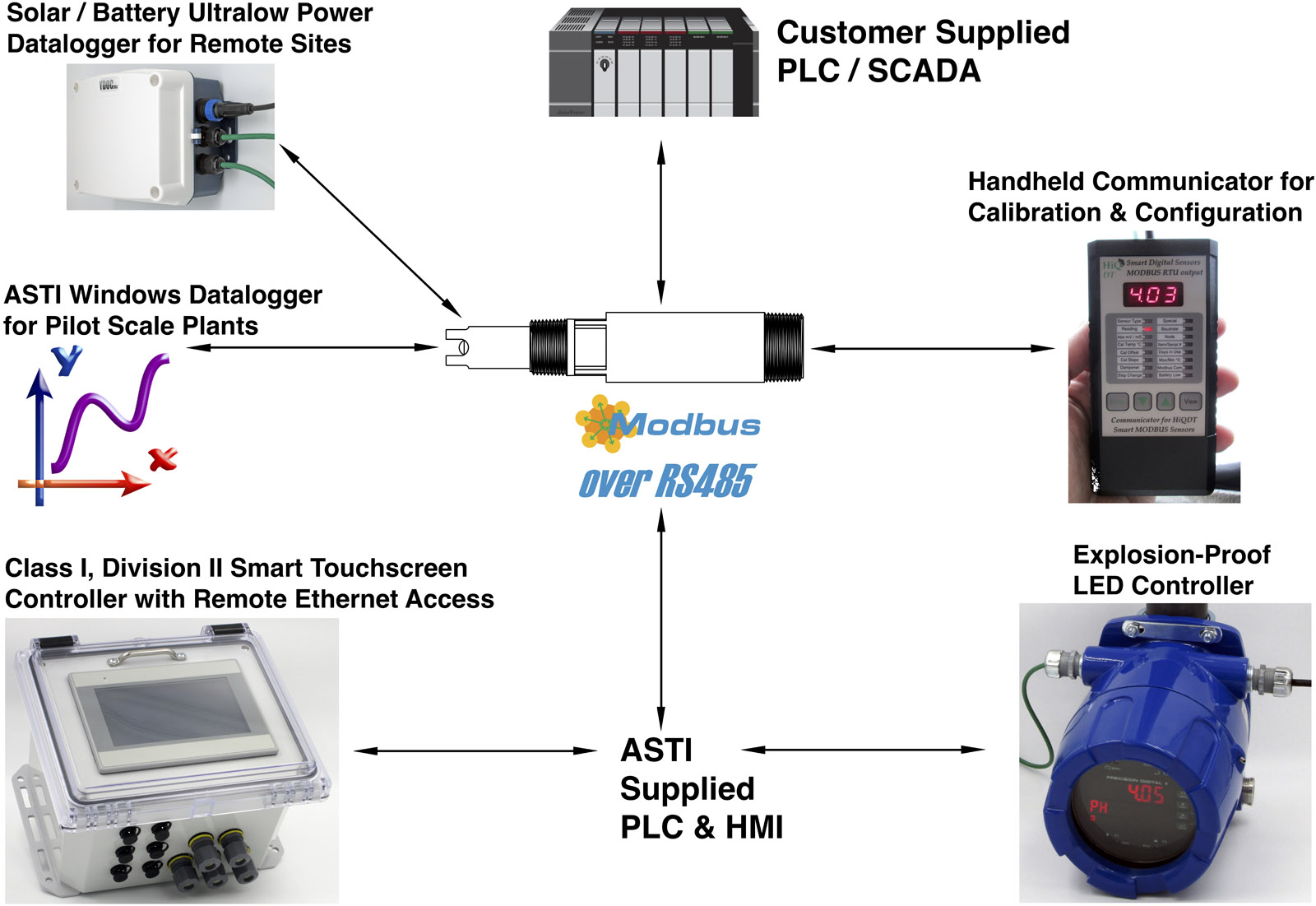

HiQDT smart digital sensors have integral RS-485 MODBUS RTU communications allowing them to be connected directly with a very wide array of devices ushering a new era in continuous industrial field measurements where the brand of data acquisition & control device is decoupled from the manufacturer of the smart digital sensor giving true freedom of choice back to the customer to select their preferred vendors for each aspect of liquid analytical analysis without artificial restrictions.

The HiQDT product line is designed to allow for seamless integration with either customer supplied PLC & HMI or else available as turn-key plug and play packages from the ASTI factory ready for commissioning right out of the box. Systems are available for continuous inline measurement and control in hazarduous or safe locations employing rugged LED or advanced touchscreen interfaces. The same HiQDT smart digital RS485 MODBSU RTU sensor used for continuous measurements can also be employed for intermittent measurements when used with an ultralow power battery or solar datalogger to record measurements and then wirelessly transmit this data from remote site locations. ASTI Windows setup and calibration software for HiQDT smart RTU sensors allows for adjustment of all user accessible parameters as desired and is provided free of charge. The battery-powered handheld communicator provides a very simple method for plug and play calibration and setup of various adjustable parameters in the field or in the workshop. Since all calibration and configuration information is integral to the sensor this allows for plug and play hot-swap use between any mating device that has been properly configured without any special user action required in the field.

Introduction to Novel Smart Digital HiQDT Measurement Platform

The HiQDT smart digital product line is a novel approach on how to measure, analyze, control and datalog pH, ORP, Dissolved Oxygen (D.O.), Ion Selective & Conductivity (EC) parameters for industrial processes automation, discharge compliance & environmental monitoring in the Industrial Internet of Things (IIoT) age.

Core Structure of HiQDT RS485 MODBUS RTU Smart Digital Sensors Installed into Field Service

RS485 MODBUS RTU MASTERS:

NOTE: HiQDT sensors are RS485 MODBUS RTU slaves. Only ONE (1) RS485 MODBUS RTU master device can be connected at any one moment time. See installation guide for full commissioning details.

- Programmable Logic Controller (PLC)

- Human Machine Interface (HMI) can be either local or else available via remote access

- All PLC & HMI functionality shown above is included ASTI touchscreen controllers

- PLC & HMI can be either customer supplied or ASTI provided as desired.

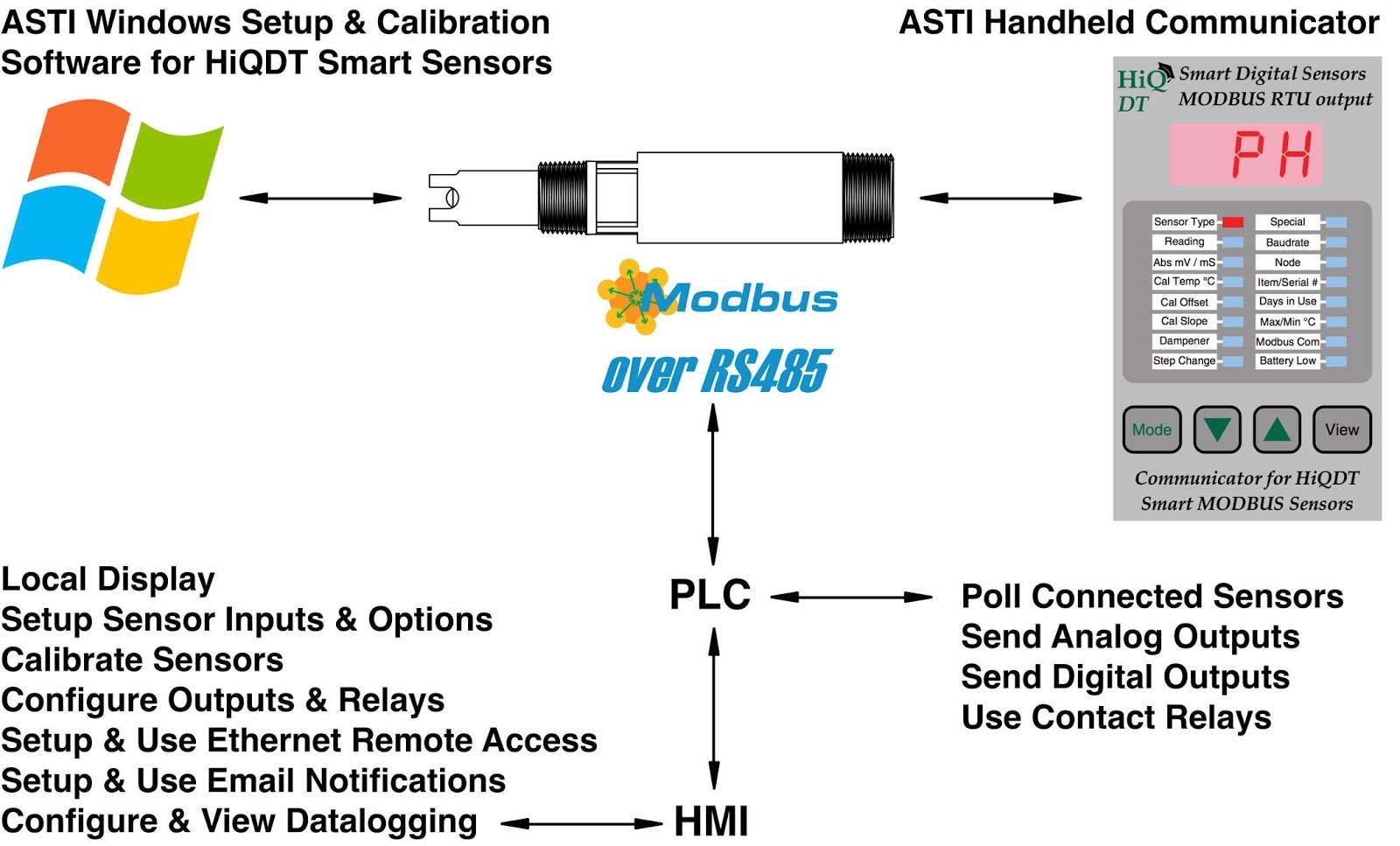

- Windows Software for Setup, Configuration & Calibration of HiQDT sensors

- Search & Assign node address & baudrate (HHC can also search & assign node address)

- Optional for configuration & calibration if these features are not implemented in HMI+PLC

- Windows Datalogging & Graphing Software records pH, ORP, Conductivity uS/cm along with computed salinity (PSU), total dissolved solids (TDS) & resistivity (MegaOhms), Dissolved Oxygen ppm & computed percent (%) saturation, Ion Selective (ISE) ppm plus temperature values

- Ideal for initial setup of modbus RTU network for commissioning

- Excellent free datalogging tool for small pilot & research scale systems without a PLC already in place to minimize development costs

- Absolute raw mV and conductivity values also recorded for diagnostic purposes

- Handheld Communicator (HHC) for use with pH/ORP Sensors or Dissolved Oxygen (D.O.) Sensors or Ion Selective (ISE) Sensors or Conductivity (EC) Sensors

- 9V battery powered operation with simple easy to use 4 button operation with bright LED

- Ready for plug & play use right out of the box with zero configuration required

Industrial Internet of Things (IIoT)

The core difference of the HiQDT smart digital sensors is that all user functionality is accessible via the open standard and royalty free RS-485 MODBUS RTU protocol. This is in contrast to the now antiquated sensors and transmitters that only provide a 0-20mA or 4-20mA current loop or 0-5 or 0-10 VDC voltage output contaning no diagnostic information whatsoever. The modern HiQDT smart digital sensors take advantage of the industrial internet of things (IIoT) where remote access to all information is available from the sensor in realtime allowing for advanced predictive maintenance and support including remote calibrations and troubleshooting. HiQDT smart digital sensors create an open and collaborative environment for process automation and liquid analytical monitoring enabling a level of connectivity and integration that is not possible with closed architectures such as HART, Profibus, Fieldbus and other proprietary platforms that force vendor lock-in to the client.

Detailed complete documentation is available for the HiQDT smart digital sensors to allow access to all of the user adjustable configuration parameters, analytic data & calibration functions and values as well as sending the engineered temperature compensated process pH & ORP values in very high resolution. Analytics allow for predictive analytics to schedule maintenance in a proactive manner as well as robust monitoring of the process no matter the control system that is currently employed at the given facility. This HiQDT platform gives customers the freedom to interface these sensors with any PLC of their choice so long as it can act as a RS-485 MODBUS RTU master. Support for RS-485 MODBUS RTU master mode on PLC now is very common, if not altogether standard, even for entry level PLC, many of which are also now available with cost-effective remote ethernet access options.

1MF-3EA-HiQ4FP-HiQDT-4EA-SCG-PS12 Triple Input Bridge Box with integral 12VDC power supply to energize sensors for 85 to 265 VAC line powered operation with PNCE 6331-6631-HiQDT-WPC Slurry, Sulfide & Extreme Dehydration Resistant Submersible RS-485 MODBUS RTU Smart pH Sensor with waterproofing style “C” sealing option on left and PN 6353-HiQDT-STUB Immersion Slurry Resistant “STUBBY” style back-end cable assembly shown on the right. All connectors are NEMA 6P rated waterproof with bridge box NEMA 4X rated ready for field installation. White & green leads on left are modbus network in while white & green leads on right are out to modbus network.

Significance of HiQDT Platform in the Field

The major paradigm shift of the HiQDT smart digital MODBUS sensors and the Industrial Internet of Things (IIoT) means that not only process values can be viewed remotely but ALL functionality that is possible locally standing in front of the HiQDT controller can be accomplished remotely with robust security and administration for access control. That means no more trips out in to the field to assist clients with commissioning or troubleshooting for any issue that is simply a matter of configuring software or controller options. All of these types of changes can be made remotely with the HiQDT platform building upon the power of the Industrial Internet of Things (IIoT) and the accessibility through wired and wireless networks both from a Windows PC as well as cellular connected iOS and Android smartphones and tablets. Proactive site support & maintenance with email notifications upon user configurable trigger conditions such as max or min process values & temperatures, max days in service since calibration or relay being energizied allows for.

Installation Schemes DIY to Turn-Key Plug & Play

It is not necessary to be a PLC programmer to use the HiQDT smart digital MODBUS sensors. The HiQDT product platform includes a complete set of tightly integrated mating controllers and process equipment to interface the HiQDT sensors with robust factory support to provide completely turn-key field ready plug and play packages. The packages include integral scalable analog outputs, configurable MODBUS RTU and TCP slave digital communications, programmable contact relays, datalogging and full remote access capabilities for all functionality that is possible locally. Although all functionality can be achieved programming your own PLC, the convenience of factory supplied and supported controllers for smaller projects or fast delivery situations might still be very desirable. Factory supplied HiQDT touchscreen controllers include autobuffer calibration with temperature correction for pH buffers to ensure accurate results no matter the operator at the site. Plug & play packages available for hazarduous areas requiring Class I, Division II approval as well as for even the most stringent Class I, Division I explosion-proof rated areas with severe & aggressive environments.

|

Windows software performs the tasks which are detailed below.

|

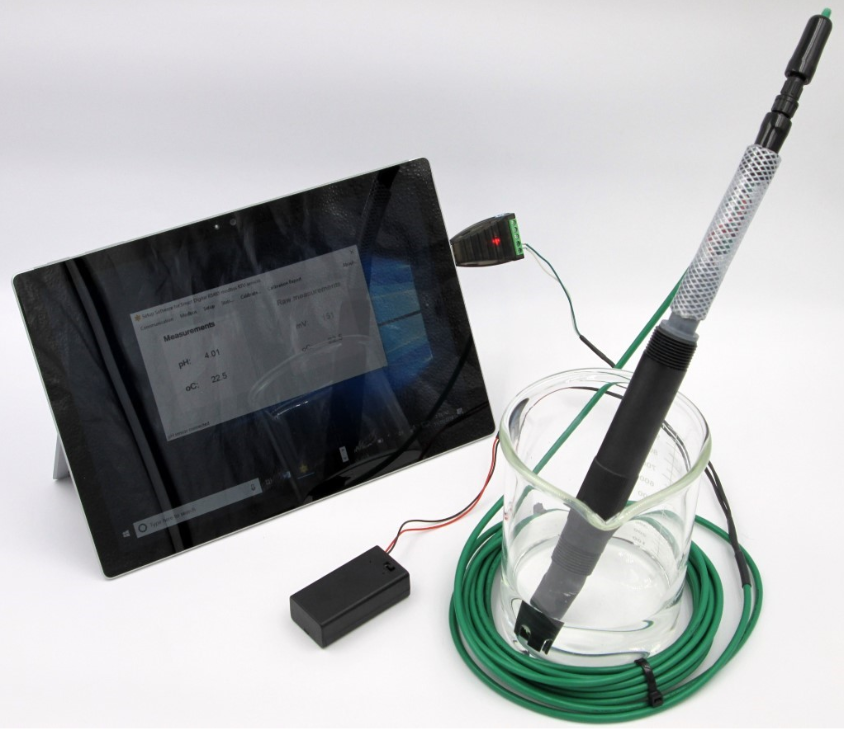

Low-cost battery-powered bridge assembly to power smart digital HiQDT MODBUS RTU sensors and RS-485 to USB converter to interface with Windows software on PC or surfacet tablet touchscreen. Alternate bridge box configurations include waterproof NEMA 4X battery powered assemblies suitable for use in the field as well as AC line powered bridge box assemblies commonly used for permanent installation for desktop Windows computers. A special bridge box assembly also exists which uses only the 5V power from the USB port to energize the sensor. This special all USB powered bridge box assembly can simultaneously energize up to 3 each smart HiQDT MODBUS RTU sensors and utilizes a special integral isolated 5VDC to 12VDC converter. |

Communicator for HiQDT pH, ORP, D.O., ISE & EC Sensors

Handheld Communicator (HHC) manual for use with pH/ORP Sensors Handheld Communicator (HHC) manual for use with Dissolved Oxygen (D.O.) Sensors Handheld Communicator (HHC) manual for use with Ion Selective (ISE) Sensors Handheld Communicator (HHC) manual for use with Conductivity (EC) Sensors |

Handheld Communicator (HHC) has 3-digit display & 16 LEDs to show analytic data & readings as well as to calibrate & configure sensor. Programming is done with 4 keys. ‘Mode’ key toggles & navigate to each LED. ‘Up’ or ‘Down’ buttons scroll options & adjust values. ‘Mode’ key makes selections & saves entries. ‘View’ key used to provide additional information for the given LED mode (see manual for specifics in each LED). |

HHC with PN 6353-HiQDT-STUB Slurry Resistant “STUBBY” MODBUS RTU Smart Digital pH Sensor compact configuration particularly ideal for portable field use. |

Factory Supplied Turn-Key Ready Touchscreen Controllers for HiQDT Sensors

Factory supplied controllers for the HiQDT pH, ORP, Dissolved Oxygen (D.O.), Ion Selective & Conductivity (EC) sensors built on very well established Maple Systems PLC & HMI hardware.

HiQDT-CTRL-6CH six (6) channel controller with 7.0” color touchscreen is shown above. The three (3) and six (6) channel controllers using the 7.0 inch color touchscreen are available in configurations that are suitable for use in hazarduous Class I, Division II locations while the two (2) channel controllers using the smaller 4.3 inch color touchscreen (not shown above) are only suitable for use in safe non-hazarduous installation locations.

DOWNLOAD COMPARISON CHART OF HiQDT SMART DIGITAL CONTROLLER PACKAGES

Features and Options:

- Assembly Type

- NEMA 4X rated supplied with all hardware ready for immediate wall or pipe mounting.

- Power Configurations

- 85-265 VAC (PS1 or PS1C1D2), Non-Isolated 18 to 75 VDC (PS2), Non-Isolated 9.5 to 18 VDC (PS3) or Non-Isolated 9 to 36 VDC (PS4) power type

- Display Typee

- 4.3 Inch Touchscreen Controller for Two (2) Channel Controller

- 7.0 Inch Touchscreen Controller for Six (6) Channel and Three (3) Channel Controllers

- Certifications

- All HiQDT controllers have CE, CSA & UL approvals for use in non-hazarduous areas

- 3 & 6 Channel controllers available for use in Class I, Division II hazarduous locations

- Calibrations

- pH

- Auto buffer pH calibration mode

- 7.00 & 6.86 pH buffers for asymmetric potential (A.P.) offset

- 4.00 & 1.68 pH buffers for acid slope

- 9.18, 10.00 & 12.45 pH buffers for alkaline (base) slope

- Auto buffer pH calibration mode

- ORP

- Manual offset adjustment anywhere in the range

- Conductivity

- Automated zero dry in air calibration

- Separate slope (a.k.a. gain or span) for standard range mode and high range mode

- Ultralow range mode sensors uses single unified slope (a.k.a. gain or span)

- Dissolved Oxygen

- Fully automated calibration for D.O. sensors dry in air (no solutions required)

- Ion Selective

- Manual Offset and Slope calibration to standard solutions

- In-Situ Offset while sensor in service for agreement with offline grab sample analysis

- Temperature

- Manual temperature offset calibration anywhere in the range for all sensor types

- pH

- Analog Outputs

- Up to 6 each isolated & scalable 4-20mA or 0-10VDC; software selectable for each channel

- Contact Relays

- Up to 18 each SPST relays rated up at 2A @ 230VAC or 30VDC for use as alarms or closed loop local control

- Two (2) each relays are assigned to process value per measurement channel

- Digital Input & Output

- MODBUS TCP SLAVE (a.k.a. MODBUS over ethernet) for all registers on each sensor for every factory touchscreen controller to interface upstream PLC, SCADA or DCS if desired.

- HiQDT controller is ALWAYS dedicated RS-485 MODBUS RTU master to HiQDT sensors

- Datalogging

- Large 32GB capacity to record all process values, analytic and calibration values over time

- Remote access to logged data over FTP on local subnet, public IP or even behind firewall

- Logged data can be converted to Excel for further workup and analysis of all channels

- Date stamping on data using RTC for all factory supplied touchscreen HiQDT controllers

- Special Features for Touchscreen Controllers used with 3TX-RTU-D Universal Transmitters

- All sensor types can use default node address for any channel when using the verison of the touchscreen controller programmed for use with the universal 3TX-RTU-D transmitter.

- Slave node address for channel is handled by 3TX-RTU-D transmitter allowing for hot-swap between any channel of same sensor type without changing sensor node.

- The location of the universal 3TX-RTU-D transmitter does not have to reside within the NEMA 4X enclosure of the touchscreen. If preferred the universal 3TX-RTU-D transmitter can be installed remote at sensor installation points and wired back to touchscreen instead. Distances up to 1,000 meters (3,280 feet) between sensor & touchscreen are suppored.

|

|

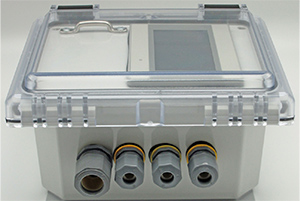

HiQDT-CTRL-2CH dual channel controller with 4.3” touchscreen shown in lid closed position. The 2 each HiQ4FP female panel mount connector are NEMA 6P rated waterproof hot-swap plug & play with the HiQDT sensors with the HiQ4M mal snap connectors. |

HiQDT-CTRL-6CH six channel controller with 7.0” touchscreen shown in lid closed position. For the triple channel configuration there would exist only 3 each of the HiQ4FP female panel mount connectors. All packages are NEMA 4X pre-installed with all necessary cable glands ready for field use. |

|

|

| HiQDT-CTRL-2CH dual channel controller package with 4.3” touchscreen shown on top output side. | HiQDT-CTRL-3CH/6CH three or six channel controller package with 7.0” touchscreen shown on the top output side. |

Intelligent Monitoring & Troubleshooting of Installations without Site Visits:

- Remote Access

- Secure Maple Systems EZAccess 2.0 software offers complete remote graphical remote access to controller with interface EXACTLY the same as if in front of touchscreen LCD including encryption, tiered administration and extensive access control features.

- Windows PC Platforms as well as Android & iOS smartphones & tablets supported

- Secure Maple Systems EZAccess 2.0 software offers complete remote graphical remote access to controller with interface EXACTLY the same as if in front of touchscreen LCD including encryption, tiered administration and extensive access control features.

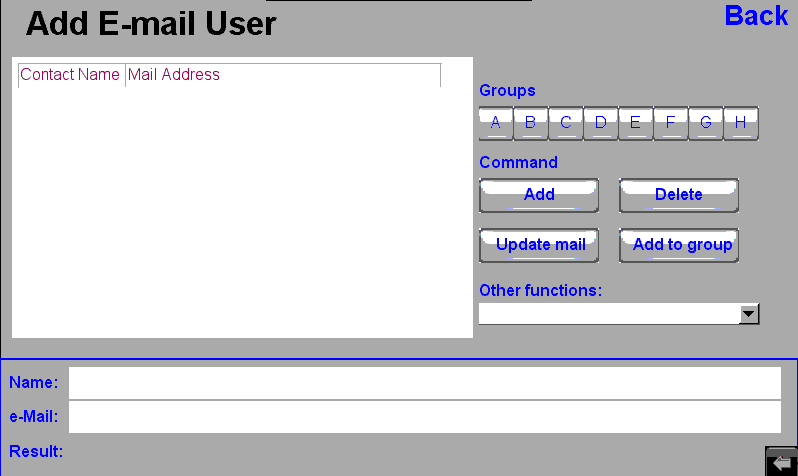

- Email Notifications

- Email notifications for all logged events such as when a relay is turned on or off based upon setpoints for the process values or temperature or if a channel loses communcation.

- Proactive monitoring & support for installed sites even without using remote access

- Email notifications for all logged events such as when a relay is turned on or off based upon setpoints for the process values or temperature or if a channel loses communcation.

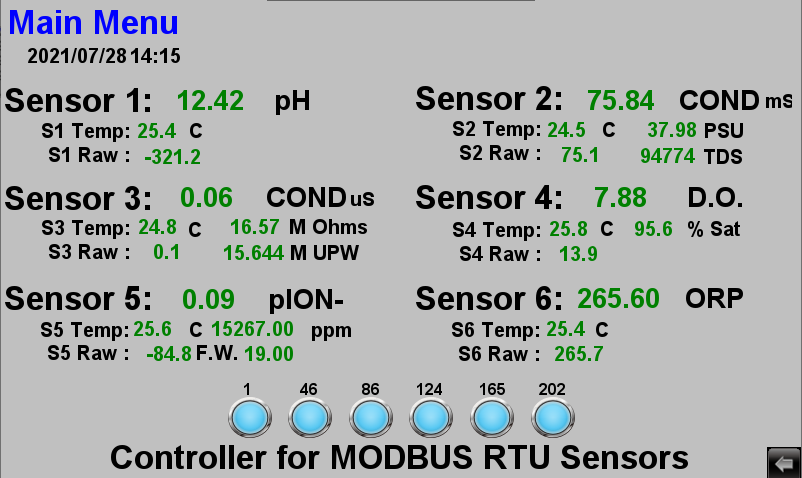

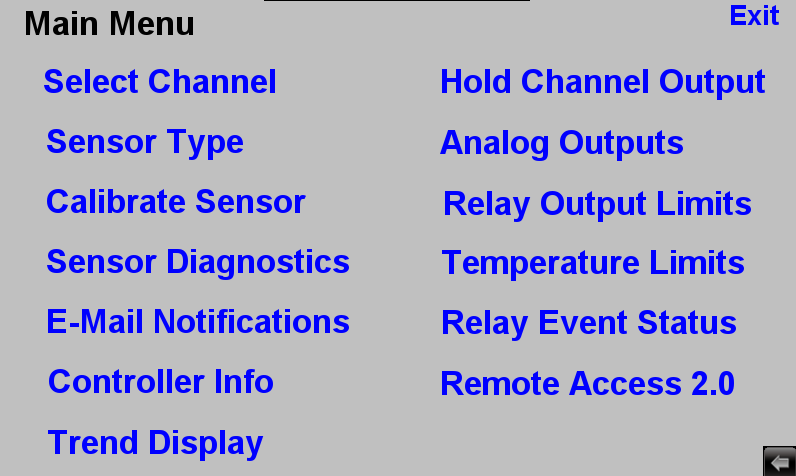

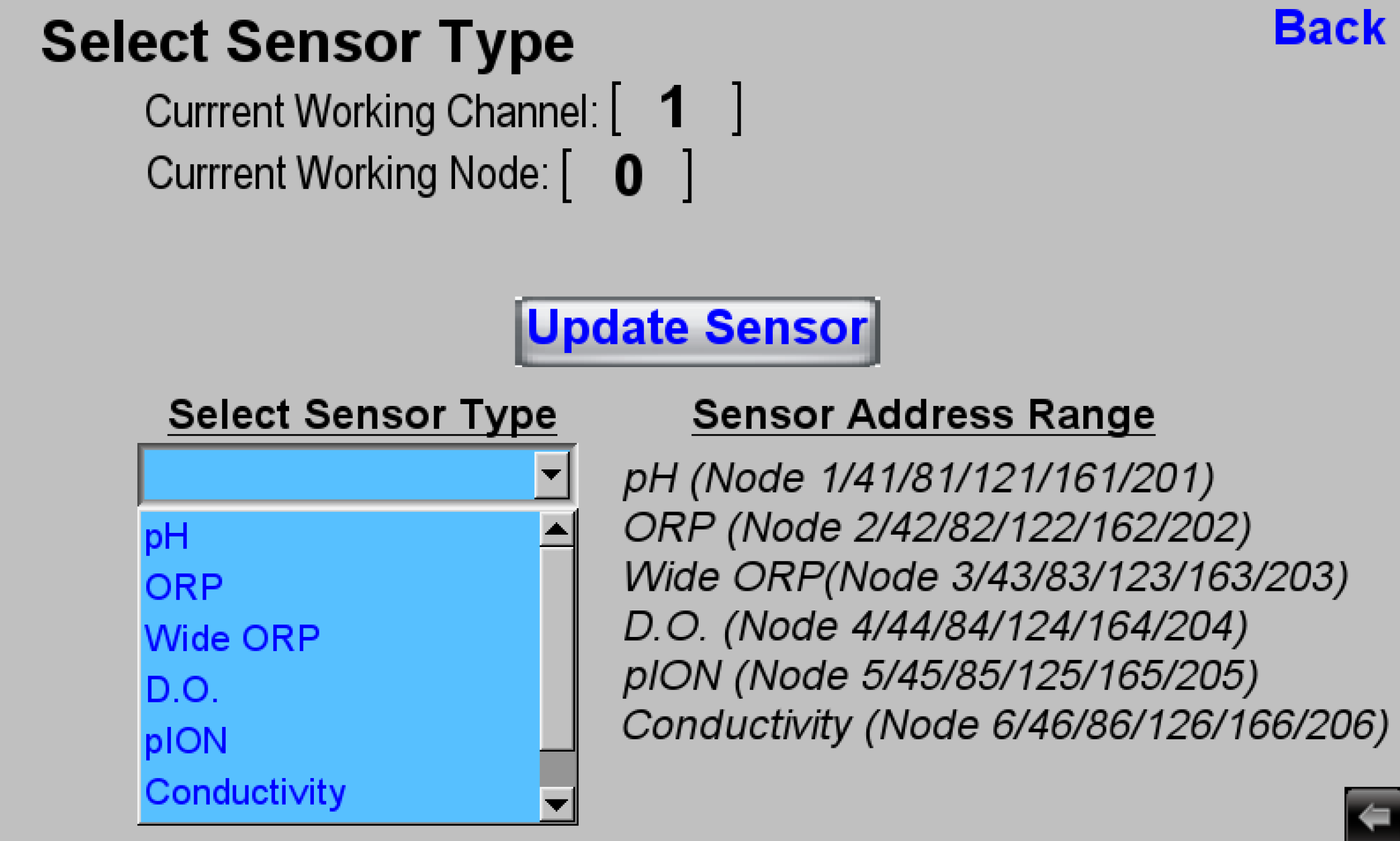

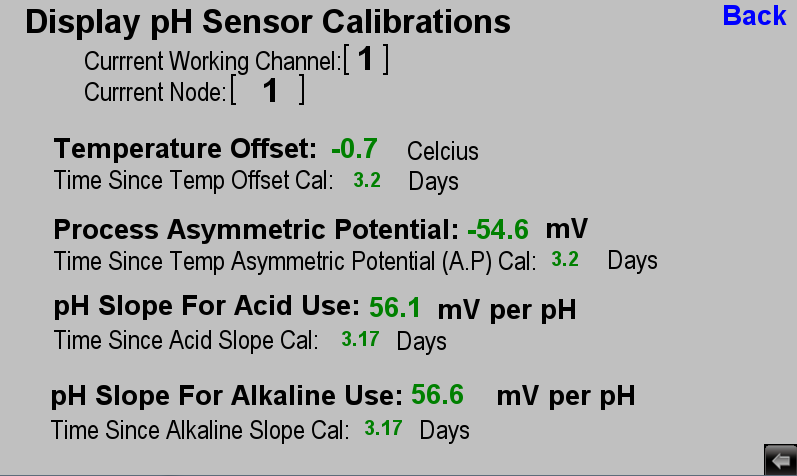

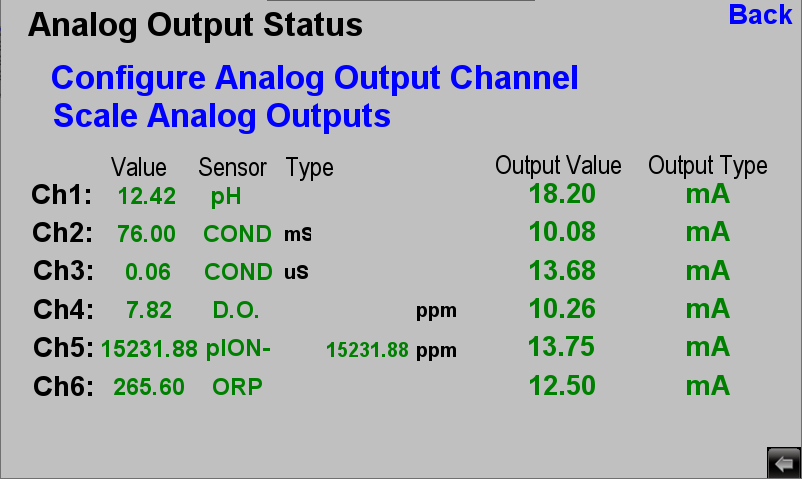

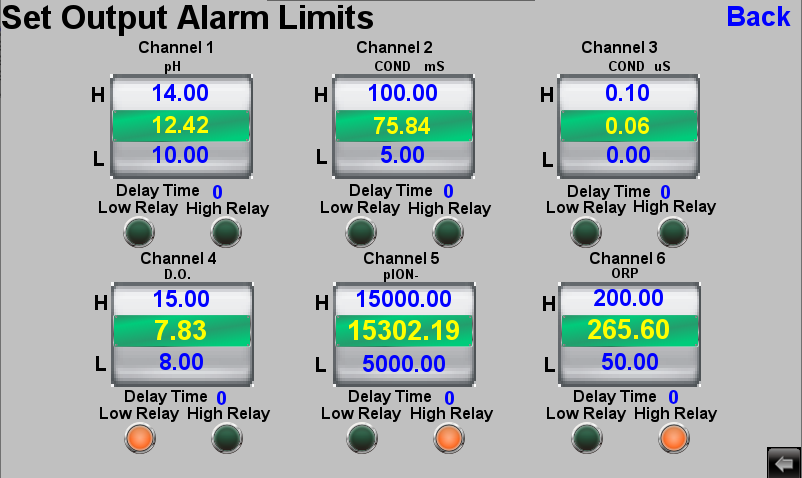

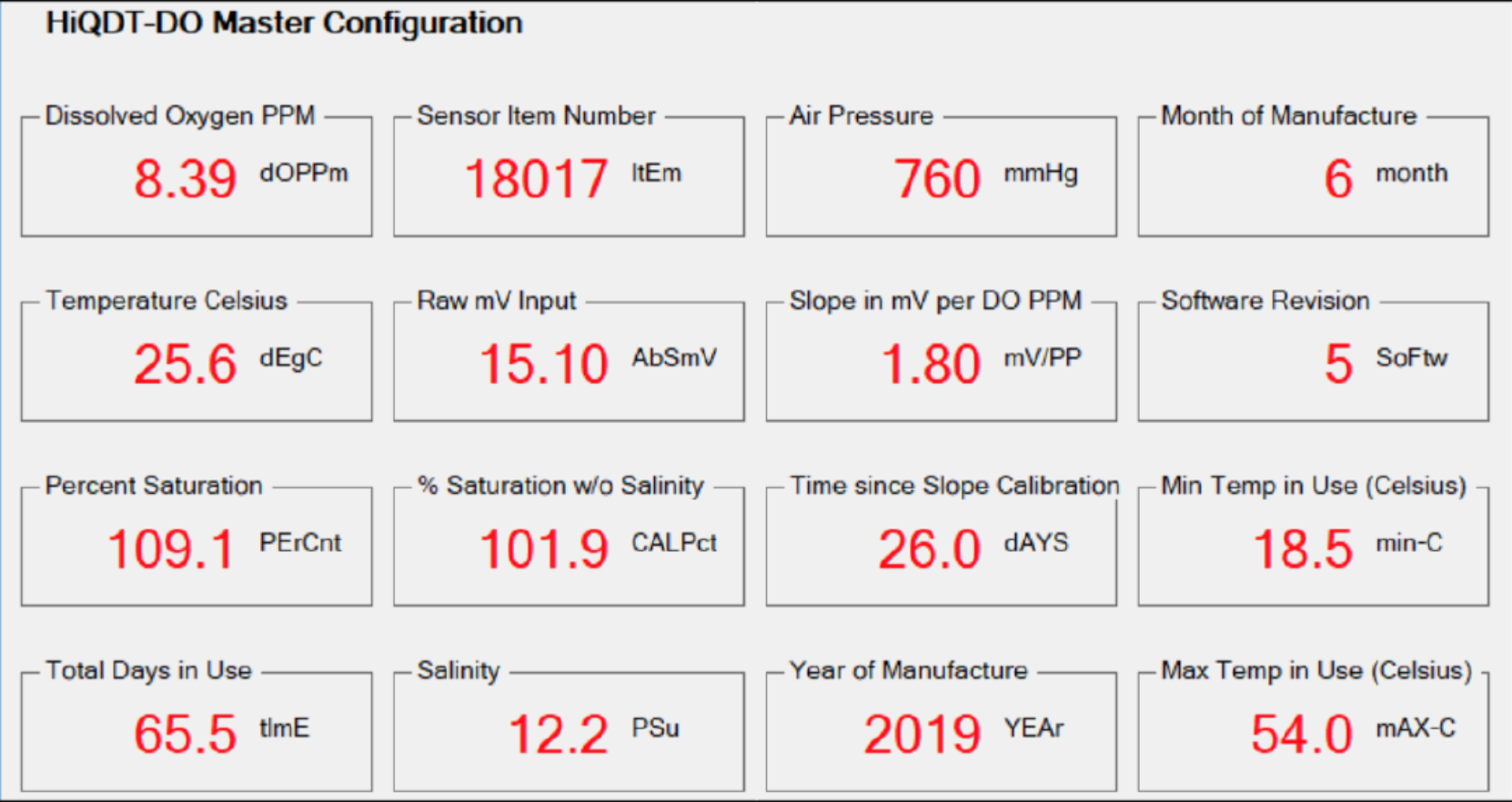

Selected Screenshots of Touchscreen Six (6) Channel Controller

|

|

Default display with all other screens accessed through the main menu. Status updates, alarms & alerts are scrolled across the top of screen. |

Main menu for main tasks & functionality of controller. Additional submenus load as needed to navigate the available features & options. |

|

|

Measurement type for each channel on unviersal controller assigned or modified at any time using smart digital hot-swap plug & play sensors. |

Sensor calibrations are displayed and datalogged including the time since calibration was last performed for best practice maintenance. |

|

|

For six channel controller there is one analog output for each sensor, isolated, scalable & on-screen selectable as 4-20mA or 0-10VDC. |

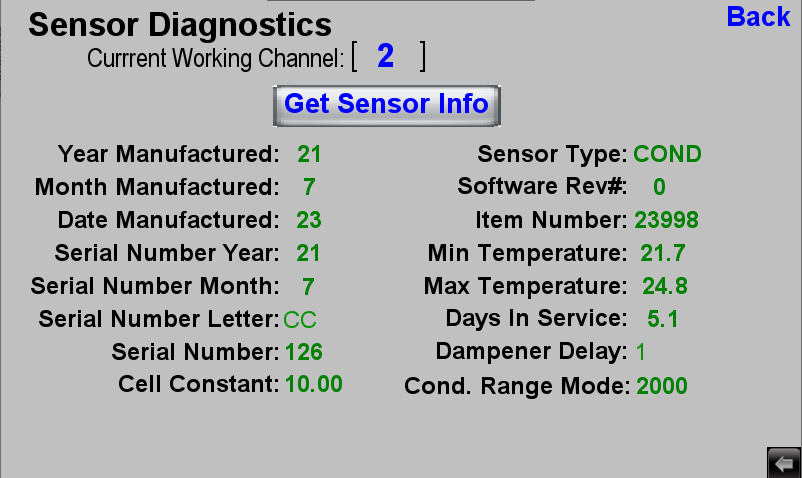

Analytic info for each channel shown & datalogged for details about not just process values but also the sensors used for the measurements. |

|

|

| High & Low relay process setpoints for each channel with time delay. | Along with full secure remote access, email notifications are sent for each event. |

3TX-RTU-D Universal Transmitters for Smart RTU Sensors

|

|

ILLUSTRATION OF P02 MASTER & P21 SLAVE NODE ADDRESS ON 3TX-RTU-D CONFIGURATIONS WHEN INTERFACED WITH TOUCHSCREEN CONTROLLER

Example shown above is for use with touchscreen controller where channels 1, 2 & 3 are configured for pH. This scheme allows for seamless hot-swap plug and play operation without having to change the node address on the smart pH sensor no matter the channel. The 3TX-RTU-D P21 slave node address defines the channel to the touchscreen controller to which it is connected. For other sensor types the P02 and P21 node address assignments would differ but the concepts would be the exactly the same as shown above.

ILLUSTRATION OF SECURITY FEATURE OPTIONS WITH 3TX-RTU-D TRANSMITTERS

HiQDT-EX-LEDTX Explosion-Proof (EX) Controllers for Hazardous Locations for Smart Digital HiQDT MODBUS RTU pH, ORP, D.O. and EC Sensors

Smart Digital HiQDT MODBUS RTU sensors are interfaced with NEMA 6P waterproof snap connectors ensuring that sensor maintenance requires no screwdriver use of any kind. The Safe-Touch through-glass button programming means that no IR remote or magnetic device is needed to interface the HiQDT-EX-LEDTX controller for simple operation with just your finger in the field. |

|

HiQDT-NEMA4X-LEDTX Controllers for Safe Non-Hazardous Locations for Smart Digital HiQDT MODBUS RTU pH, ORP, D.O. & Conductivity Sensors

Ratings & Approvals and Power Options

|

The HiQDT-NEMA4X-LEDTX controller shown above is the simplest package in the master configuration offering hot-swap plug and play operation with precalibrated smart digital MODBUS RTU sensors for fool-proof operation. The dual channel configuration (not shown above) has 2 each of the controllers panel mounted in the same NEMA 4X enclosure ideal for redundancy or when multiple parameters need to be measured at the same installation location. Snooper configuration has 4 each connection ports standard in the NEMA 4X enclosure packages. Inquire to factory if you are planning ot use 1/8-DIN panel mount installation scheme for snooper to ensure practice commissioning. |

DEFAULT 16 MODBUS REGISTERS DISPLAYED FOR MASTER CONFIGURATION OFHIQDT-EX-LEDTX & HiQDT-NEMA4X-LEDTX CONTROLLERS WITH SMART DIGITAL HiQDT MODBUS RTU pH, ORP, D.O. & CONDUCTIVITY (EC) TYPE SENSORS

MASTER CONFIGURATION NOTES:

- Scaling for 4-20mA analog output is full measurement range of the given sensor type by default, although this can be readily modified with ScanView Windows software as desired for your paticular installation.

- Dual Isolated Analog Output (DIAO) Expansion module for HiQDT-NEMA4X-LEDTX controller adds two (2) each fully independent programmable loop-powered 4-20mA analog outputs

- Basis for analog output(s) can be calibrated and temperature compensated process value obtained from connected smart digital MODBUS RTU pH, ORP, dissolved oxygen (D.O.) or conductivity (EC) sensor.

- For dissolved oxygen (D.O.) sensors units can be chosen aS ppm or percent (%) saturation.

- For the conductivity (EC) sensors units can be μS/cm or mS/cm or else salinity (PSU) or Total Dissolved Solid (TDS) ppm. For ultralow ranges MegaOhm (MΩ) resistivity units are available.

- Four (4) each Fully Independent and Programmable 5A rated Contact Relays Suitable for Alarm, On/Off Control with Deadband as well as sophisticated control using Time Proportional Control (TPC) algorithms

- Scanview Configuration Windows software uses either local USB or RS-485 serial port for remote interface

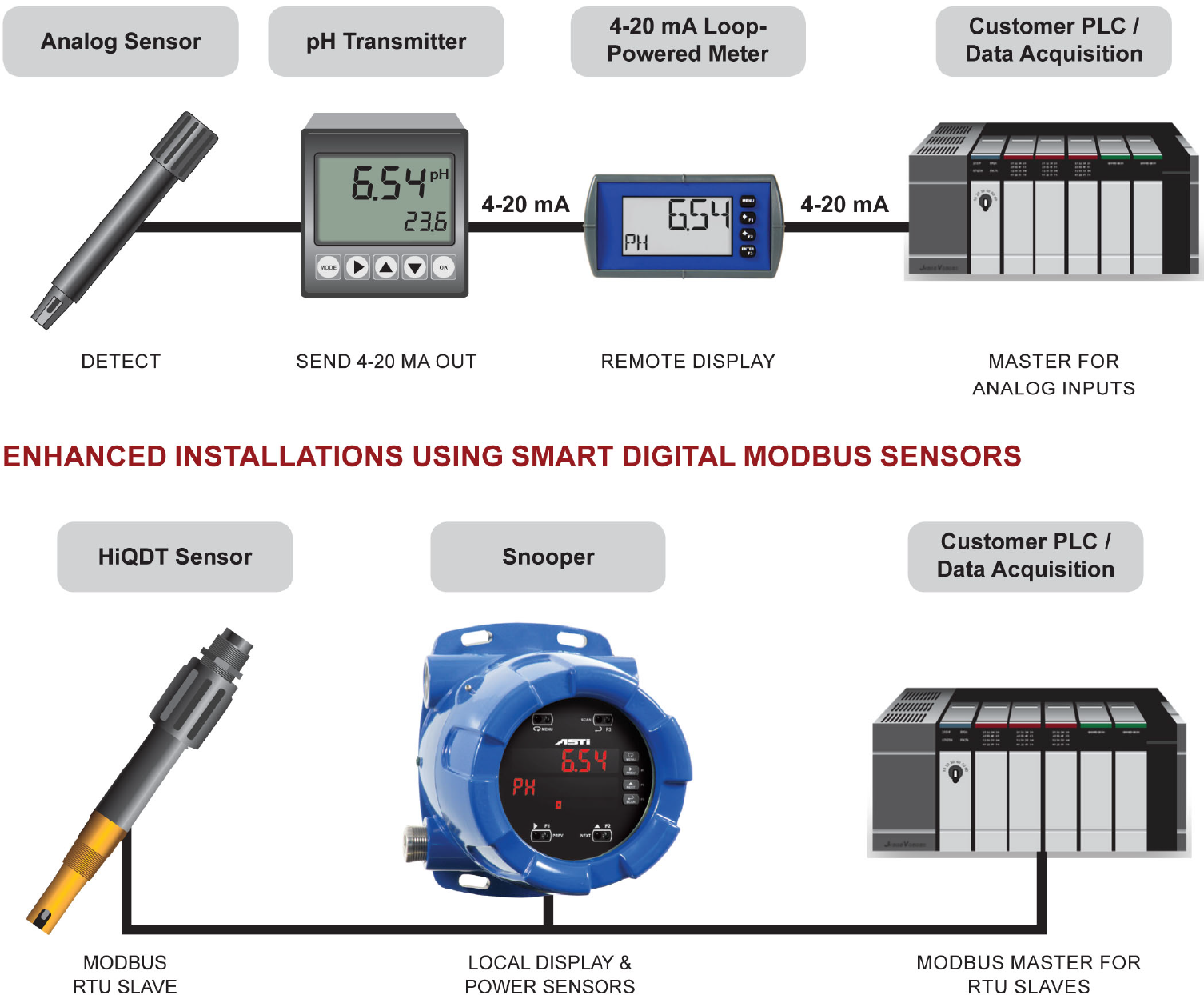

SNOOPER CONFIGURATION OF HIQDT-EX-LEDTX & HiQDT-NEMA4X-LEDTX for Smart HiQDT MODBUS RTU pH, ORP, D.O. & Conductivity sensors

SNOOPER CONFIGURATION NOTES:

- Snooper configuration for smart HiQDT MODBUS RTU sensor slaves on bottom illustration can be correlated to 4-20mA loop-powered meter for analog control systems on top illustration where both devices serve as local display between the control system and the sensor and/or transmitter.

- Up to 8 each HiQDT MODBUS RTU sensors can be powered and polled in snooper configuration when installed in non-hazardous locations (max 1 each supported for hazardous EX type areas).

- HiQDT-EX-LEDTX & HiQDT-NEMA4X-LEDTX snooper configurations provide isolated power & isolated RS-485 serial port to fulfill installation requirements of HiQDT MODBSU RTU sensors.

- Any registers that are to be displayed and/or used as the basis of any analog output or contact relays must be polled by customer programmed MODBUS RTU master (PLC, SCADA,…etc).

DOWNLOAD LED EX, NEMA4X & PANEL CONTROLLER SUMMARY & COMPARISON CHART

COMPARISON CHART OF CONTROLLER OPTIONS FOR SMART DIGITAL HiQDT MODBUS RTU pH, ORP, DISSOLVED OXYGEN (D.O.), ION SELECTIVE (ISE) & CONDUCTIVITY (EC) SENSORS

NON-HAZARDOUS SAFE LOCATIONS ONLY

| Description | 3TX Modular Transmitter Module | NEMA 4X LED Controller | 2 Channel Touchscreen |

|---|---|---|---|

| Part Number | 3TX-3MF-XH-XEA-RTU-D-PS | HiQDT-NEMA4X-LEDTX-XH-XCH-PSAC12 | HiQDT-CTRL-2CH-PS1 |

| Channels | 1 | 1 to 3 for Master Mode, Max 8 for Snooper Mode | 2 |

| Enclosure | BUD NBF-32410 | Precision Digital PDA2811 | Serpac I152HL,TCBG |

| Approvals | CE | CSA/UL Safe Areas | CSA/UL Safe Areas |

| Display | Single Line 3 digit LED | Dual Line 6 digit LED | 4.3 Inch Color Touchscreen |

| Analog Out Types | 1 each 0-20mA or 4-20mA for each Channel | 1 ea 4-20mA (3 ea 4-20mA for Triple Channel Configuration) | 2 each 4-20mA or 0-10VDC |

| Analog Out Value(s) | Process Value Only | Any of 16 Polled Parameters from Connected Sensor(s) | Either Process & Temp from Ch1 or Process Only from Ch1 & Ch2 |

| Analog Out Polarity | Selectable Non-Inverted or Inverted | Selectable Non-Inverted or Inverted | Non-Inverted Only |

| Analog Trim Calibration | Yes | Yes via Push-Button + LED Display or Scanview Windows Software | No |

| Digital Out | MODBUS RTU Slave | RS-485 MODBUS RTU (Snooper) | MODBUS TCP Slave |

| Relays | Optional 2 each when 3TX-REL module is added | 4 each SPDT (Form C) | 4 each SPST |

| Datalog | Yes, with Optional Free Datalogging Windows Software | Yes, with Optional Free ScanView USB Software | Yes, Data stored on integral USB Flash Drive, accessible via FTP |

| Remote Access | Yes, via RS-485 MODBUS RTU Slave when P24 set to "All" | Yes, over RS-485 with ScanView Software | Yes, via EZ Access 2.0 & VNC with Email Notifications |

NON-HAZARDOUS SAFE LOCATIONS ONLY

| Description | 3 Channel Touchscreen | 6 Channel Touchscreen |

|---|---|---|

| Part Number | HiQDT-CTRL-3CHS-PS1 | HiQDT-CTRL-6CHS-PS1 |

| Channels | 3 | 6 |

| Enclosure | Serpac I352HL,TCBG | Serpac I352HL,TCBG |

| Approvals | CSA/UL Safe Areas | CSA/UL Safe Areas |

| Display | 7.0 Inch Color Touchscreen | 7.0 Inch Color Touchscreen |

| Analog Out Types | 6 each 4-20mA or 0-10VDC | 6 each 4-20mA or 0-10VDC |

| Analog Out Value(s) | Both Process & Temp from Channels 1, 2 & 3 | Process Only from Channels 1, 2, 3, 4, 5 & 6 |

| Analog Out Polarity | Non-Inverted Only | Non-Inverted Only |

| Analog Trim Calibration | No | No |

| Digital Out | MODBUS TCP Slave | MODBUS TCP Slave |

| Relays | 6 each SPST | 18 each SPST |

| Datalog | Yes, Data stored on integral USB Flash Drive, accessible via FTP | Yes, Data stored on integral USB Flash Drive, accessible via FTP |

| Remote Access | Yes, via EZ Access 2.0 & VNC with Email Notifications | Yes, via EZ Access 2.0 & VNC with Email Notifications |

| NOTE: Previously purchased HiQDT-CTRL-3CHS-PS1 Three (3) Channel Controller can be upgraded to HiQDT-CTRL-6CHS-PS1 Six (6) Channel Controller (Upgrade process requires shipping back to factory) | ||

HAZARDOUS LOCATION RATED

| Description | Explosion-Proof LED Controller | 3 Channel Touchscreen | 6 Channel Touchscreen |

|---|---|---|---|

| Part Number | HiQDT-EX-LEDTX-PSAC | HiQDT-CTRL-3CH-PS1C1D2 | HiQDT-CTRL-6CH-PS1C1D2 |

| Channels | 1 for Master, Max 8 for Snooper | 3 | 6 |

| Enclosure | Precision Digital Aluminum EX | Serpac I352HL,TCBG | Serpac I352HL,TCBG |

| Approvals | FM, CSA, ATEX & IECEx | CSA/UL Hazardous Areas | CSA/UL Hazardous Areas |

| Locations | Class I, Div I, Groups B,C,D | Class I, Division II | Class I, Division II |

| Display | Dual Line 6 digit LED | 7.0 Inch Color Touchscreen | 7.0 Inch Color Touchscreen |

| Analog Out Types | 1 each 4-20mA | 6 each 4-20mA or 0-10VDC | 6 each 4-20mA or 0-10VDC |

| Analog Out Value(s) | Any of 16 Polled Param from Sensor | Both Process & Temp from Channels 1, 2 & 3 | Process Only from Channels 1, 2, 3, 4, 5 & 6 |

| Analog Out Polarity | Selectable Non-Inverted or Inverted | Non-Inverted Only | Non-Inverted Only |

| Analog Trim Calibration | Yes, via LED or Windows Software | No | No |

| Digital Out | RS-485 MODBUS RTU (Snooper) | MODBUS TCP Slave | MODBUS TCP Slave |

| Relays | 4 each SPDT (Form C) | 6 each SPST | 18 each SPST |

| Datalog | Yes, with Optional Free ScanView USB Software | Yes, Data stored on integral USB Flash Drive, accessible via FTP | Yes, Data stored on integral USB Flash Drive, accessible via FTP |

| Remote Access | Yes, via RS-485 with Optional Free Scanview Software | Yes, via EZ Access 2.0 & VNC with Email Notifications | Yes, via EZ Access 2.0 & VNC with Email Notifications |

| NOTE: Previously purchased HiQDT-CTRL-3CH-PS1C1D2 Three (3) Channel Controller unit can be upgraded to HiQDT-CTRL-6CH-PS1C1D2 Six (6) Channel Controller (Upgrade process requires shipping back to factory) | |||

NOTE 1: All controller assemblies are NEMA 4X or higher rated.

NOTE 2: All Packages are for 85-265 VAC line powered operation for consistency of comparison

NOTE 3: DC powered package are also available for all controller configurations.

NOTE 4: LED controllers require sensors to be calibrated with either handheld communicator (HHC) or Windows software. All other controllers can performed calibration directly with connected sensor

NOTE 5: ION SELECTIVE SENSORS ARE ONLY COMPATIBLE WITH 3TX-RTU-D and TOUCHSCREEN CONTROLLERS.

NOTE 6: All controllers ready for plug & play with smart digital sensors with integral panel connector(s) except EX controller, which also needs female snap to tinned lead (HiQ4F-Xm-TL) extension cable

Tools for Setup, Configuration & Calibration with minimal work on customer PLC

- Free of charge Windows software is provided with all HiQDT sensors to accomplish all user adjustable setup and configuration steps as well as calibration tasks.

- ONLY the HiQDT Windows software can change the baud rate of HiQDT sensors

- Create calibration certificate reports for archival quality assurance compliance and advanced analytics to optimize process maintenance as well as the sensor life cycle

- Setup, configuration and calibration tasks can also be accomplished by a small compact lightweight battery-powered handheld communicator (HHC) for HiQDT sensors if preferred.

- TThis handheld communicator can also serve as a portable measurement system allowing industrial HiQDT sensors to be used both for spot analysis and troubleshooting in the field.

- If desired the HiQDT Windows software and/or handheld communicator can perform all complex tasks meaning that only scaling of the process pH, ORP, Conductivity, Dissolved Oxygen (D.O) and Ion Selective (ISE) values & temperature readings is needed to commission HiQDT sensors in the field.

- Field commissioning can be done in minutes for those familiar with general setup of RS485 MODBUS RTU slaves using HiQDT smart digital modbus sensor implementation guide.

Zero Configuration Working Right out of the Box

- Since the HiQDT MODBUS sensors are smart digital type they can be pre-calibrated to be ready to deploy right out of the box by simply plugging sensors in the mating keyed waterproof connector. Only requirement is to supply either AC or DC power as defined by the package type ordered.

- The HiQDT sensors can be hot-swapped between different controllers with the only caveat that the MODBUS node address is valid for location to where it is connected (see installation guide).

- Factory supplied packages can be supplied pre-configured sensors & controllers such that upon powering equipment and connecting sensors it is immediately measuring and datalogging values.

- This means TRUE ZERO CONFIGURATION working right out of the box. Ideal where very fast commissioning is required or when many installation points are started in a narrow time window..

- This means TRUE ZERO CONFIGURATION working right out of the box. Ideal where very fast commissioning is required or when many installation points are started in a narrow time window..

Core Features for Smart Digital HiQDT Sensors

- Store their configuration settings and all calibration values in the sensor allowing for complete portability in terms of where maintenance tasks such as cleaning and recalibration are performed.

- Engineered process pH & ORP values sent are always calibrated and temperature compensated. Calibrated temperature and absolute mV values are also sent with (04) read_input_registers call.

- In principle up to 247 HiQDT sensors can be installed onto a single RS-485 MODBUS RTU master, although it is recommended to use a repeater after 32 nodes (inquire to factory for assistance).

- High speed MODBUS serial communications ensure low-noise operation in industrial process environments at distances up to 1,000 meters (3,280 feet). Support for long cable runs allows for installation of the mating controller to the HiQDT sensors at any convenient location at the site.

- All smart digital HiQDT sensors standard with waterproof NEMA 6P rated quick disconnect snap connectors for convenient field commissioning and maintenance. Waterproof snap connectors allow for seamless simple hot-swap plug and play functionality with mating PLC controllers.

- Portable battery powered handheld communicator for portable spot measurements using same industrial HiQDT industrial sensors used for continuous inline field measurements. This is ideal for spot analysis as well as troubleshooting field readings at any location of interest.

- Very fast booting HiQDT sensors have readings ready to view or record in as little as 2 seconds.

- Ideal for intermittent operation from dataloggers or else spot portable field measurements.

Capabilities of Smart Digital HiQDT MODBUS pH, ORP, D.O. & Conductivity (EC) Sensors

- Supported pH Range from -2.00 to +16.00 (Max Resolution 0.001pH unit)

- Actual pH range for particular sensor model is defined & limited by specifications

- Supported Standard Range ORP Mode from -1,000 to +1,000 mV in (Max Resolution 0.1mV)

- Raw Absolute mV Resolution 0.05mV for pH or Standard Range ORP Modes

- Supported Wide Range ORP Mode from -2,000 to +2,000 mV in (Max Resolution 0.2mV)

- Raw Absolute mV Resolution 0.10mV for Wide Range Range ORP Mode

- Supported D.O. Range from 0.00 to 150.00 ppm (0.0 to 1,500.0 %) with 0.01mV Resolution

- Supported Conductivity Range and resolution varies depending upon cell constant and range mode.

- Inline pH/ORP Installations up to 150 ℃ Maximum Temperature & Maximum Pressure 200 psig

- Fully Submersible Installations up to 125 ℃ max (if sensor is rated to at least 135 ℃)

- Inline max temperature for particular sensor model is defined & limited by specifications

- Minimum temperature -35 ℃ for Extreme Dehydration Resistant Series (Inline or Submersible)

- For Inline Conductivity Sensors Temperatures up to 205 ℃ and Pressure up 500 psig supported

Calibrations Features for Smart Digital HiQDT Sensors

The smart digital HiQDT pH & ORP sensors integrally store these calibrations which are used to compute and send calibrated and temperature compensation pH, ORP and temperature values. The time in service since each calibration type was last performed is stored for analytic purposes.

- Temperature Offset for HiQDT pH, ORP & Dissolved Oxygen (D.O.) sensors

- mV Offset for HiQDT ORP sensors & Asymmetric Potential (Offset) for HiQDT pH* & ISE sensors

- Acid Slope for HiQDT pH* sensors (used when media measured is less than pH7)

- Alkaline Slope for HiQDT pH* sensors (used when media measured is more than pH7)

- Slope for HiQDT Ion Selective (ISE) sensors is typially preprogrammed at factory for characteristic response for planned process environment and condition but can be changed in the field if necessary.

- Slope for D.O. sensors (no offset required for galvanic Dissolved Oxygen Sensors with true zero)

- Zero Dry in Air offset and Wet Slope Calibration for Conductivity (EC) Sensors * Factory HiQDT Controller supports autobuffer pH calibration: 7.00 & 6.86 pH buffers for asymmetric potential (A.P.), 4.00 & 1.68 pH buffer for acid slope & 9.18, 10.00 & 12.45 pH buffer for alkaline slope

Core Setup, Configuration & Analytic Features for Smart Digital HiQDT Sensors

- The smart digital HiQDT pH, ORP & D.O. sensors store the following core and analytic information:

- Type – pH, Standard & Wide Range ORP, Dissolved Oxygen (D.O.), Ion Selective (ISE) or Conductivity

- Dual pH/ORP all-in-one sensors appear as separate pH & ORP for setup & calibration

- Baudrate – 9600 or 19,200 kbps

- Note: All sensors on MODBUS network must have same baudrate

- Node – User adjustable from 1 to 247 – Max HiQDT sensors on one network, use repeater after each 32 HiQDT sensors; See HiQDT installation guide & controller manual for best practice setup

- Temperature Compensation Coefficient – Default is classical 0.198mV per ℃ Nernstian value

- Adjustable temperature compensation from 0.000 to 0.999 mV for special applications

- Smoothing dampener for process readings (time averaging) – From 1 to 30 seconds

- Delay from boot to send values (important setting for intermittent battery powered operation)

- Sensor Item Number (Discrete Coding for Exact Configuration & Options)

- Serial Serial Number (for Complete Traceability back to Factory)

- Max (up to 210℃) & Min (down to -40℃) Temperature in Service (when sensor is energized)

- Total Days in Use – stored in units of hours with a max value of 65,535 equating to 7.5 years

- Software Revision of Board - for support purposes and troubleshooting

- Software Revision of Board - for support purposes and troubleshooting

- Software Revision of Board - for support purposes and troubleshooting

Installation Configuration Available for Smart Digital HiQDT Sensors

- The entire line of built-to-order IOTRONTM and ZEUSTM pH and ORP sensors with all possible configurations and options available smart digital HiQDT style. Support for all inline & immersion and fully submersible installations, twist lock quick disconnect bayonet style installations as well as sanitary and HOT-TAP valve retractable installation schemes.

- Smart digital HiQDT sensors available in single parameter pH only and ORP only configurations or dual pH/ORP all-in-one configurations where both pH & ORP are measured in one sensor.

- Dual pH/ORP smart digital HiQDT sensors require suitable waterproofing sealing option for space needed for 2nd sensor board to measure two parameters in a single sensor.

- Dual pH/ORP smart digital HiQDT sensors require suitable waterproofing sealing option for space needed for 2nd sensor board to measure two parameters in a single sensor.

- AST-DO-UNIVERSAL HiQDT rugged industrial dissolved oxygen (D.O.) sensors available for inline, immersion, twist lock quik disconnect, sanitary & HOT-TAP valve retractable installations.

- Smart Digital Conductivity (EC) Sensors available for inline, immersion, submersible sanitary and HOT-TAP valve retratable type installations. For standard and high range mode sensors calibrated and temperature compensated readings of units can be μS/cm or mS/cm or else salinity (PSU) or Total Dissolved Solid (TDS) ppm. For ultralow ranges MegaOhm (MΩ) resistivity units are also available.

Universal 3TX-RTU-D Transmitters for Smart Digital HiQDT MODBUS RTU Sensors

- Provides local display & isolated, scalable & reversible 0-20mA or 4-20mA output

- Simultaneously functions as MODBUS RTU master to smart HiQDT MODBUS RTU sensor and MODBUS RTU slave to upstream PLC. ALL sensor registers are accessible from MODUS RTU slave port.

- Security parameter P24 allows for field adjustable access control levels on MODBUS RTU slave port anywhere from read only for sensor and transmitter, to write only for transmitter or else allowing for full read & write access to both sensor and transmitter.

- Display current mA output based upon current sensor reading & scaling setup on transmitter.

- Display current mA output based upon current sensor reading & scaling setup on transmitter.

- Universal software automatically detects measurement type of mating sensor & loads all necessary associated parameters without any additional user action required once node address of sensor is entered.

- Customized user-defined default settings can be programmed each 3TX-RTU-D unit without charge

- Download the 3TX-RTU-D documentation for further details on the specific features and usage.

Compatibility of Smart HiQDT MODBUS RTU sensors & 3TX Transmitters with MODBUS

- HiQDT pH, ORP, Dissolved Oxygen (D.O.), Ion Selective (ISE) and Conductivity (EC) sensors can be used on the same RS-485 MODBUS network as the 3TX transmitters with the RS-485 MODBUS RTU output option. In this way any existing analog pH, ORP, conductivity, dissolved oxygen (DO) and ion selective (ISE) sensors interfaced with 3TX-pH, 3TX-CON, 3TX-DO or 3TX-ISE transmitter (respectively) can share the MODBUS network for sending the process values together with smart HiQDT MODBUS RTU sensors.

- Only the usual caveats apply such as all nodes having the same baudrate and that a unique node address must exist for each device. Whereas the badurate and node address can be changed from the display on the 3TX transmitter the baudrate and node for the HiQDT sensors can only be changed with the provided free of charge Windows HiQDT setup and calibration software.

- The intelligent digital 3TX-HiQ-pH transmittersinterfaced to the smart digital HiQ pH & ORP sensors can share the same MODBUS network as the smart digital HiQDT MODBUS RTU sensors as well as the 3TX transmitter with MODBUS output option.

- Free Windows Datalogging & Graphing software logs process pH/ORP/DO/ISE/EC values, temp. & absolute raw input from any HiQDT pH/ORP/DO/ISE/EC sensors on same network as 3TX transmitters. For dissolved oxygen sensors the ppm and percent (%) saturation & temperature values are logged. For conductivity the uS/cm values are logged along with the PSU or TDS if desired. For ultralow range measurements the resistivity value in MegaOhm units can also be logged if desired.

- Windows Datalogging & Graphing Software is an excellent commissioning tool to test all devices on MODBUS network are functioning correctly before connecting to the main PLC.