AST-DO-UNIVERSAL Rugged Industrial Dissolved Oxygen Smart Digital RS-485 MODBUS RTU Sensor for Inline Twist Lock Quick Disconnect, Immersion, Submersion, Sanitary & HOT-TAP Installations for Continuous Measurement in Tough Applications like Abrasive Slurries & High Turbidity

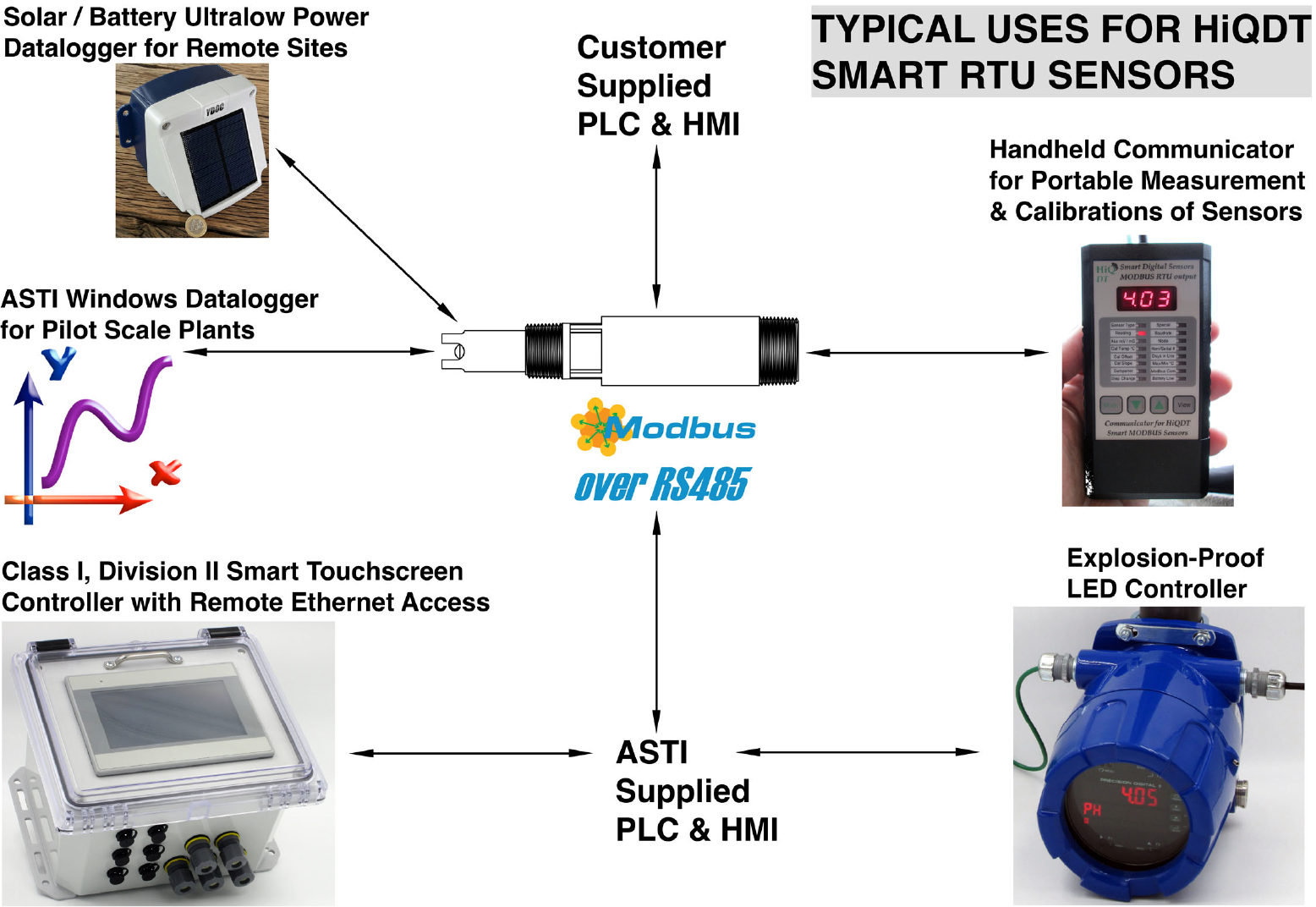

The HiQDT smart digital sensors have integral industry standard RS-485 MODBUS RTU communications allowing them to be connected directly with a very wide array of devices thus ushering in a new era in industrial field measurement where the brand of data acquisition and control device is altogether decoupled from the manufacturer of the smart digital sensor giving true freedom of choice back to the customer to select their preferred vendors for each aspect of the continuous liquid analytical electrochemical analysis without any artificial restrictions.

Close-Up on galvanic DO measuring cell of dissolved oxygen sensor in convertible configuration in fully assembled state ready to use.  Disassembled galvanic DO measuring cell ready for rebuilding. Cathode & anode on front tip of sensor are shown to the bottom right. High stability thick membrane installed into cap is shown immediately above. Membrane & electrolyte solution are easily replaced in just minutes when required. There is a virtually unlimited sensor lifetime achieved with this rebuildable type galvanic DO cell ensuring a very low total cost of ownership. |

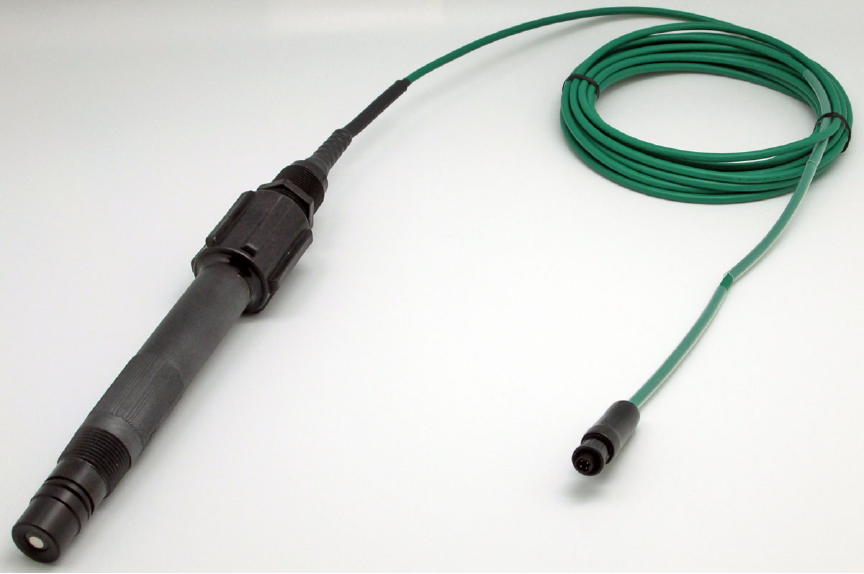

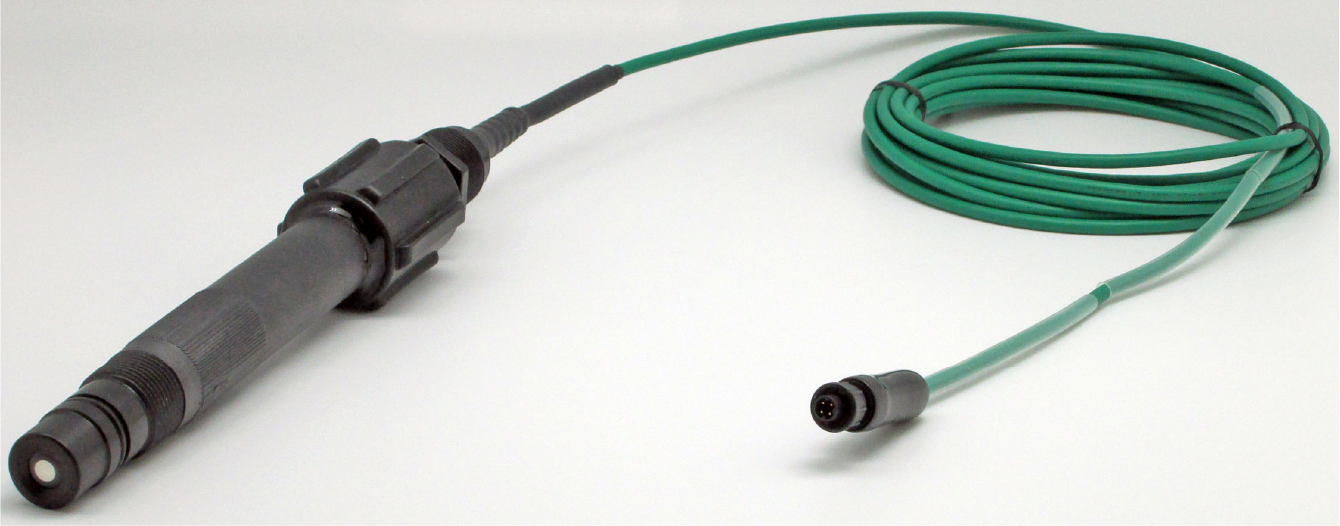

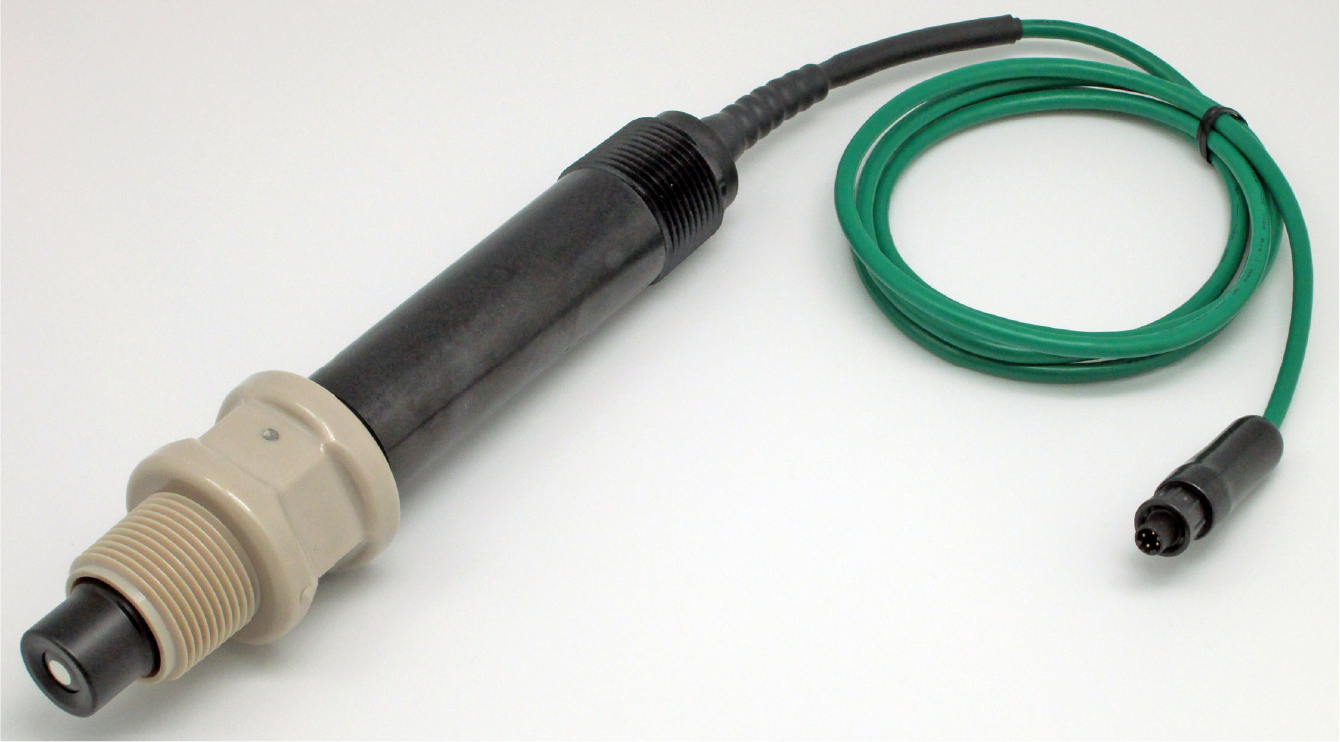

AST-DO-UNIVERSAL-CONVERTIBLE galvanic dissolved oxygen sensor shown in smart digital HiQDT MODBUS RTU configuration with optional extended 12 meters (40 feet) integral green cable and waterproof NEMA 6P rated snap connector. Installations up to 1,000 meters (3,280 feet) total cable length can be supported in the field by means of extension cables and/or bridge box assemblies. Calibrations are stored in smart digital sensor meaning that rebuilding of galvanic dissolved oxygen cell and dry in air calibration can be performed at any location of convenience and then installed into the field on a hot-swap plug and play function by any operator without special knowledge. |

The AST-DO-UNIVERSAL smart digital MODBUS RTU dissolved oxygen sensor is a robust industrial grade sensor measures the dissolved oxygen ppm and percent (%) saturation values including salinity correction. The probe is very rugged and easy to use with automated dry in air smart calibration suitable for use in the toughest industrial, municipal, environmental and aquaculture applications.

Photos for Visualization of Universal Convertible Installation Style for Smart Digital D.O. Sensors for Inline, Immersion and Submersible Use

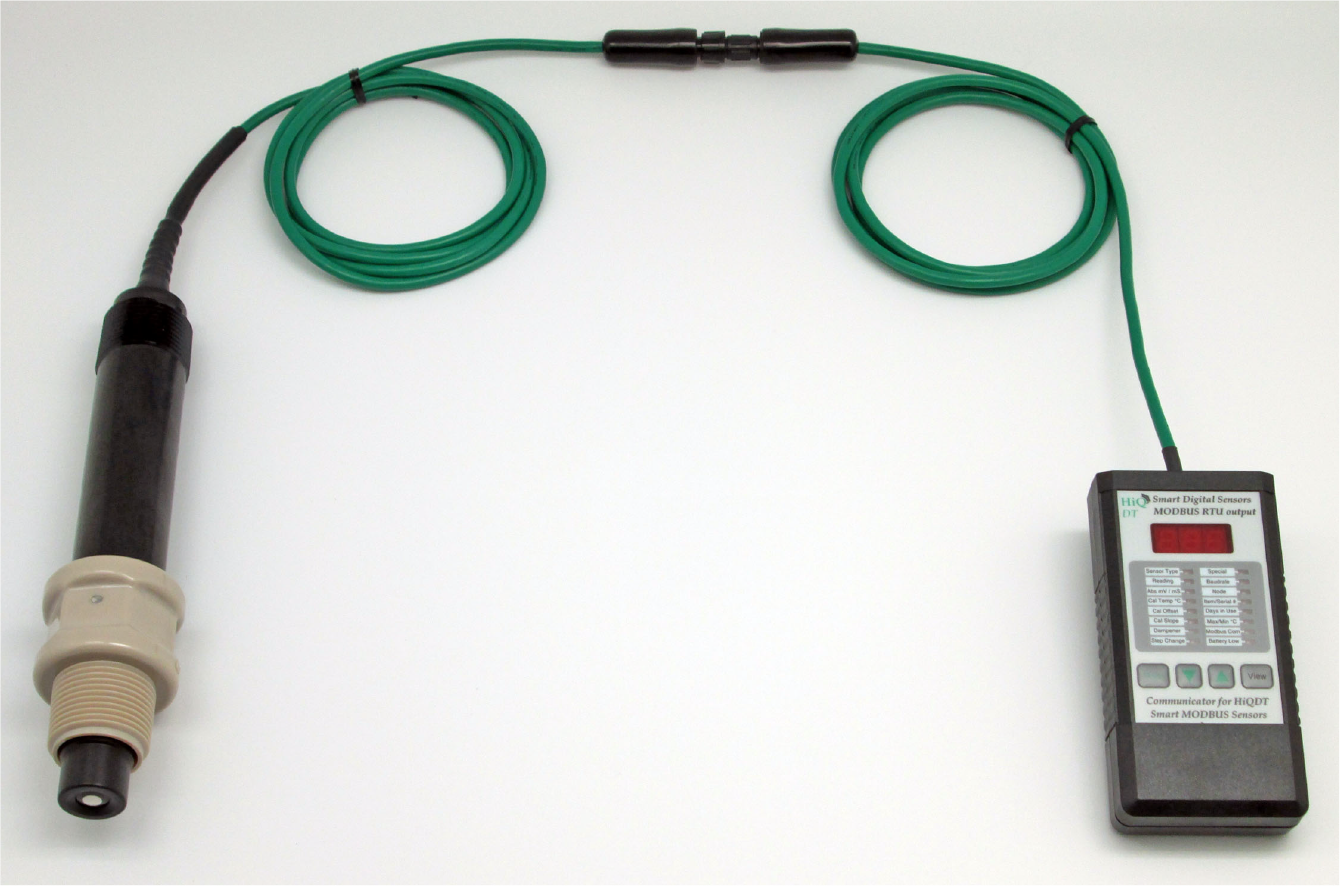

Portable battery powered Handheld Communicator (HHC) is a very fast and convenient method to perform the fully automated dry in air calibration for the HiQDT MODBUS RTU dissolved oxygen sensors. All user entered values such as the air pressure and salinity can be entered as well as other user adjustable parameters such as the dampener (time averaging smoothing function). In addition, the node of the attached sensor can be readily found with the convenient search feature. The node of the attached sensor can be modified as desired once the valid existing node is known.

DOWNLOAD PRINTABLE PDF SUMMARY FOR THE CONVERTIBLE STYLE OF THE SMART DIGITAL RS485 MODBUS RTU DISSOLVED OXYGEN (D.O.) SENSORS

AST-DO-UNIVERSAL-HiQDT SMART DIGITAL CONVERTIBLE INDUSTRIAL DISSOLVED OXYGEN (D.O.) SENSOR WITH MODBUS RTU COMMUNICATIONS

| Special Features Highlighting Unique Technical Advantages: |

Unique Features highlighting technical advantages for industrial application use

|

| Description of Most Important Common Core Features: | Rugged Industrial DO Sensor for Tough Inline, Immersion & Submersible Installs

|

| Features for smart digital HiQDT MODBUS RTU configuration in addition to common core features |

|

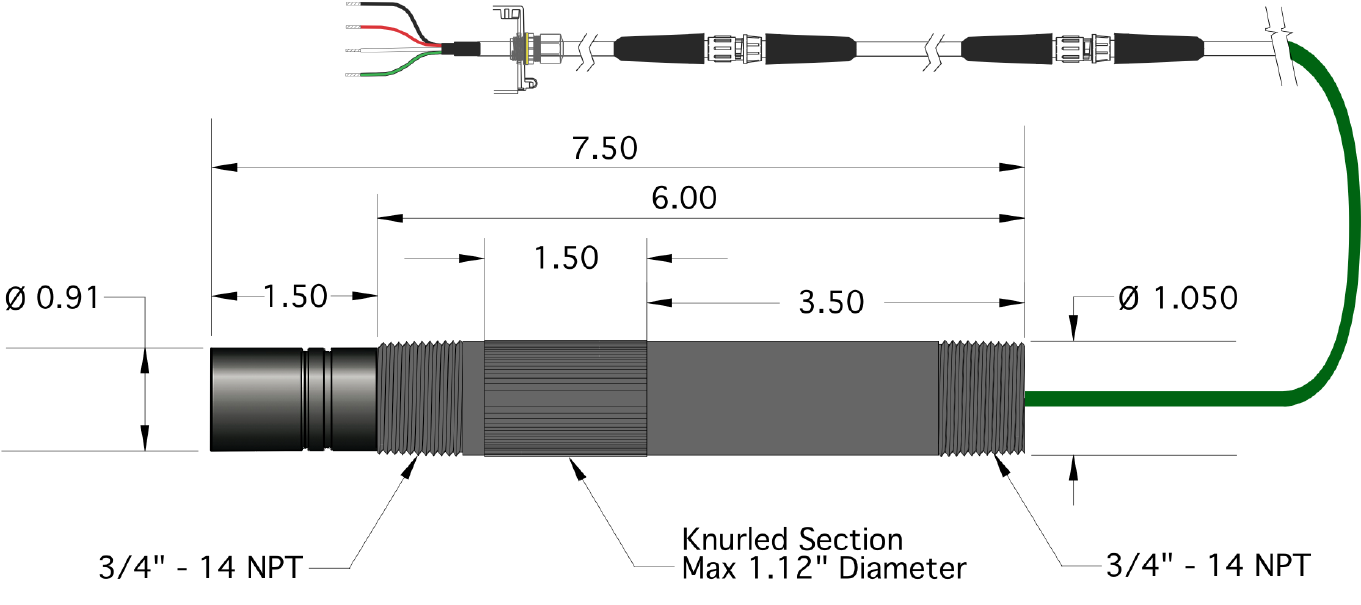

| Process Connections for Convertible Configuration: | ¾” MNPT Front Threads for Screw-in Inline Use (1.5” Std to 3.5” Special Order Max insertion) ¾” MNPT Rear Threads for Immersion Use or Submersible with Waterproofing Option |

General Sensor Specifications: |

|

| Operating Temperature Range: | -5 to +65 o C (+23 to +149 o F) |

| Operating Pressure Range: | Up to 200 bar submersion pressure; Inquire to factory for installation recommendations |

| Sensor Body Material: DO Measuring Cell Material: |

RYTON® R-4-230BL (Poly-Phenylene-Sulfone, PPS) DELRIN® (Polyoxymethylene, POM) |

| External Dimensional Details: | See AST-DO-UNIVERSAL-HiQDT Smart Digital ¾”-¾” MNPT MODBUS D.O. Sensor Drawing |

Galvanic DO Sensor Specifications:

|

|

| Measurement D.O. Range: | 0.00 to 150.00 ppm and Percent Saturation from 0.0 to 1,500.0 % (0.01pm & 0.1% Resolution) |

| Response Time: | Typically 10 to 20 seconds near ambient (response time is temperature dependent) |

| Resolution: | 1% saturation absolute |

| Repeatability: | Typically ±1% of actual measurement under the exact same conditions |

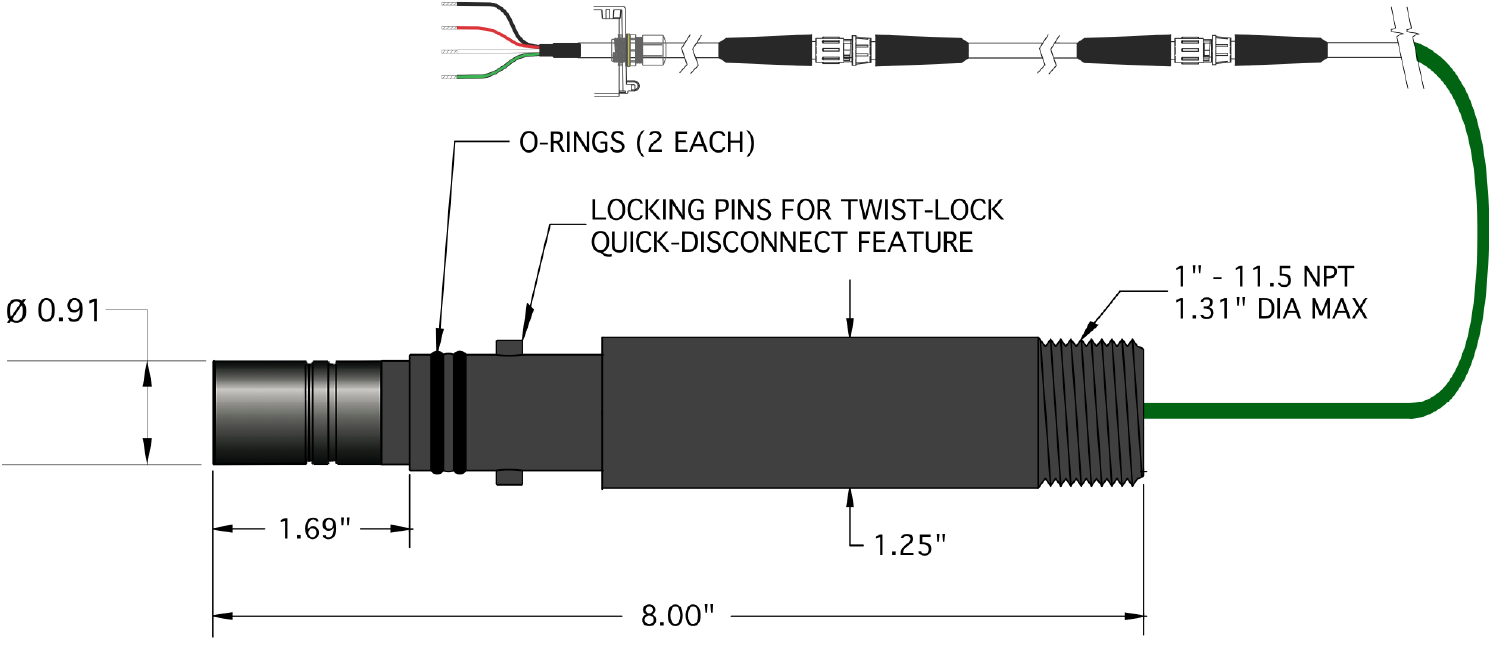

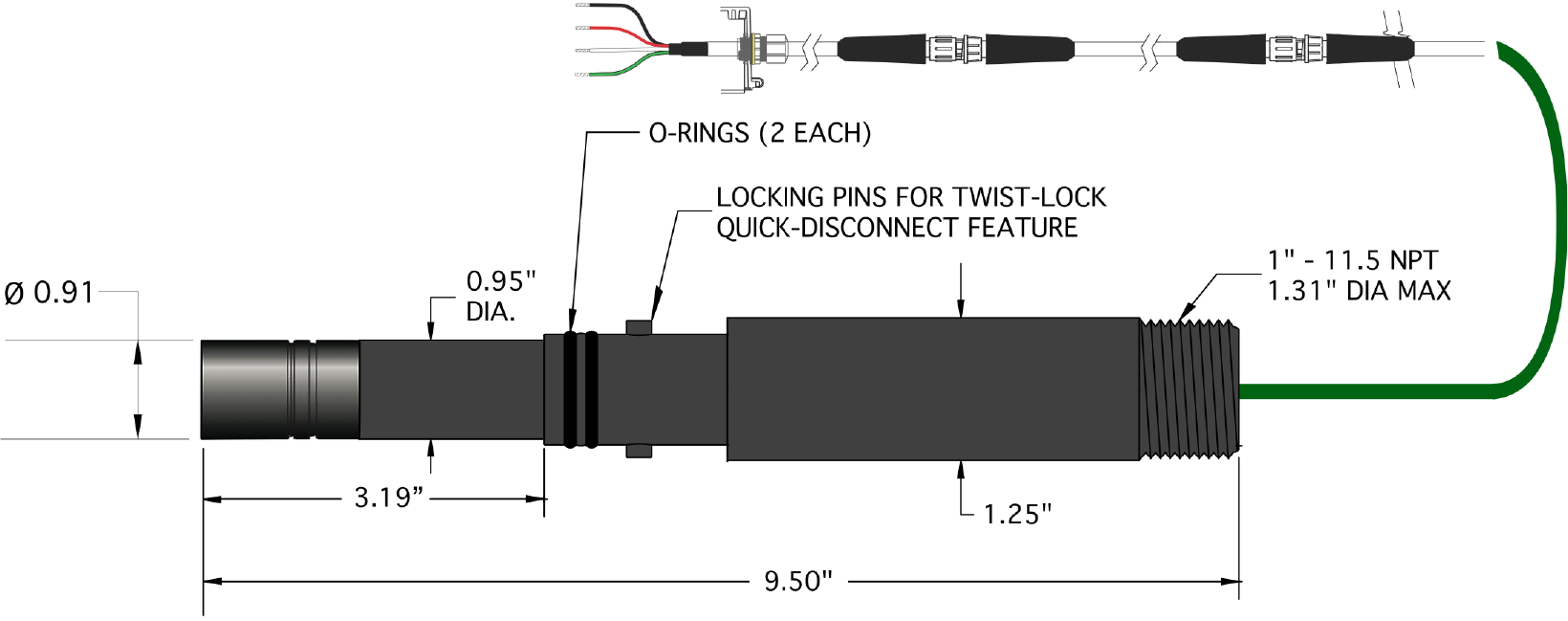

Twist Lock Quick Disconnect Bayonet Inline Installation Style Option

The AST-DO-UNIVERSAL-TWISTLOCK style is available with twist lock quick disconnect bayonet 1”MNPT receptacle for inline installations that require frequent removal from the process for cleaning. See drawings below for dimensions.

Drawing shown above in the extended inch insertion depth of 2.20 inches past start of 1" MNPT threads on twist lock receptacle.

2. Material of construction for sensor body is RYTON & galvanic DO cell is Polyoxymethylene (POM)

3. High stability thick-membrane dissolved oxygen (DO) self-powered galvanic cell with typical response of ~1 to 2 mV per DO ppm with a measurement range of 0 to 150 ppm (0 to 1,500 Percent % Saturation)

4. Smart digital HiQDT MODBUS RTU configuration use waterproof HiQ4M quick disconnect snap connector. 20 feet (6m) integral cable is standard. Extended integral cable lengths up to 75 feet (23m) available. Extension cables can achieve desired total cable lengths up to a Maximum of 1,000 meters (3,200 feet).

5. Do not use any sensor beyond the factory defined maximum temperature, flow or pressure rating.

Photos for Visualization of Twist Lock Quick Disconnect Bayonet Inline Installation Style for Smart Digital D.O. Sensors with Mating Receptacle

Handheld Communicator and Smart Digital D.O. sensor connection is waterproof NEMA 6P when interfaced ready for use in any field condition

DOWNLOAD PRINTABLE PDF SUMMARY FOR THE TWIST LOCK INLINE QUICK DISCONNECT STYLE OF THE SMART DIGITAL RS485 MODBUS RTU DISSOLVED OXYGEN (D.O.) SENSORS

AST-DO-UNIVERSAL-HiQDT SMART DIGITAL TWIST LOCK INDUSTRIAL DISSOLVED OXYGEN (D.O.) SENSOR WITH MODBUS RTU COMMUNICATIONS

| Special Features Highlighting Unique Technical Advantages: |

Unique Features highlighting technical advantages for industrial application use

|

| Description of Most Important Common Core Features: | Rugged Industrial DO Sensor for Tough Inline, Immersion & Submersible Installs

|

| Features for smart digital HiQDT MODBUS RTU configuration in addition to common core features |

|

| Process Connections for Convertible Configuration: |

|

General Sensor Specifications: |

|

| Operating Temperature Range: | -5 to +65 o C (+23 to +149 o F) |

| Operating Pressure Range: | Up to 200 bar submersion pressure; Inquire to factory for installation recommendations |

| Sensor Body Material: DO Measuring Cell Material: |

RYTON® R-4-230BL (Poly-Phenylene-Sulfone, PPS) DELRIN® (Polyoxymethylene, POM) |

| External Dimensional Details: | See AST-DO-UNIVERSAL-HiQDT Smart Digital 1” MNPT Twist Lock MODBUS D.O. Sensor Drawing |

Galvanic DO Sensor Specifications:

|

|

| Measurement D.O. Range: | 0.00 to 150.00 ppm and Percent Saturation from 0.0 to 1,500.0 % (0.01pm & 0.1% Resolution) |

| Response Time: | Typically 10 to 20 seconds near ambient (response time is temperature dependent) |

| Resolution: | 1% saturation absolute |

| Repeatability: | Typically ±1% of actual measurement under the exact same conditions |

| Typical Response & Characteristics: Range: | Typical 10mV to 40mV dry in air; Typical Slope is between 0.7mV to 3.0mV per D.O. ppm |

| Electrical Specifications: | Max 20mA current draw at 7VDC to 13VDC (Typical 15mA power consumption) |

Some Selected Examples of Recommended Applications: |

Industrial & mining abrasive slurries as well as any solution with high turbidity. Ideal for high sulfide containing media since the AST-DO-UNIVERSAL sensor is insensitive to hydrogen sulfide (H2S) gas. Any field measurement where rugged process conditions may exist. |

Storage and Shelf Life: |

Two (2) years from date of dispatch from factory stored in dry state (without electrolyte) |

1” MNPT KYNAR® PVDF and KETASPIRE® PEEK Twist Lock Receptacles for Quick Disconnect Bayonet Style Inline Installations

PEEK receptacle (left) & KYNAR receptacle (right) |

The dimensional detail drawing for the KYNAR® PVDF and KETASPIRE® PEEK Twist Lock Receptacles is linked below: |

1” MNPT KYNAR® PVDF and KETASPIRE® PEEK Twist Lock Receptacles for Quick Disconnect Bayonet Style Inline Installations | |

| The AST-DO-UNIVERSAL-SANITARY-HOT-TAP configuration is available for use with the 316SS installation hardware for sanitary tri-clover process connections or for valve retractable installations to remove the sensor will the process is still running. The installation hardware scheme for the sanitary tri-clover type processes can be visualized and the drawing downloaded from the sanitary pH/ORP configurations webpage. The installation hardware scheme for the HOT-TAP valve retractable type processes can be visualized and the drawing downloaded from the HOT-TAP valve retractable pH/ORP webpage and the process connection itself can be viewed from the HOT-TAP valve retractable hardware webpage. | |

Waterproofing Options for Fully Submersible Assemblies | |

| All of the AST-DO-UNIVERSAL configurations (Convertible, Twist Lock & Sanitary/HOT-TAP) are available for fully submersible installations with the use of an immersion tube (a.k.a. standpipe or guiderod) when a suitable waterproofing sealing option is factory installed. The option must be installed at time of order for the AST-DO-UNIVERSAL sensor and cannot be installed subsequently. The recommended waterproofing options are the WPIT sealing which is quite sufficient for most such submersible installation uses or else the WPB or WPH sealing for an even more robust sealing assembly for the most aggressive service conditions. Shown below is the WPC sealing option on the convertible configuration which is an excellent choice for situation where an immersion rod will be used for the installation location. | |

| |

AST-DO-UNIVERSAL HiQDT Smart Digital

| |

| |

| CLICK HERE for complete webpage on SMART DIGITAL HiQDT MODBUS RTU MEASUREMENT SYSTEM that contains all core information that is shared for all measurement types (pH, ORP & Dissolved Oxygen) as well as details on the ASTI supplied PLC & HMI packages for turn-ready commissioning. See installation guides for details and additional information. | |

Core Structure of HiQDT RS485 MODBUS RTU Smart Digital Sensors Installed into Field Service | |

| |

The AST-DO-UNIVERSAL smart digital RS-485 MODBUS RTU dissolved oxygen sensors comes factory calibrated and ready for immediate commissioning right out of the box. The AST-DO-UNIVERSAL sensors are available in the convertible configuration suitable for use in inline, immersion and submersible installations as well as the twist lock configuration for quick disconnect bayonet style inline installation for application where frequent removal from service is needed for cleaning to avoid coiling of the cable from repeated insertion and removal from the inline 1”MNPT receptacle process fitting. In addition, a sanitary & HOT-TAP configuration is available for use with the same 316SS sensor holder and other associated process mounting hardware as used for the pH, ORP & ISE sanitary & HOT-TAP valve retractable sensor assemblies.

| |

AST-DO-UNIVERSAL SENSOR INSTALLATION & MAINTENANCE GUIDE | |

The AST-DO-UNIVERSAL probe is easy to install. It should be placed where there is some movement in the water (approximately 1 cm/sec is enough at 7 mg/l and 13 °C for example). Ensure that the DO probe cannot strike against the tank wall and don't mount it directly above diffusers and other equipment that will give false readings. Several forms of mounting device are available for AST-DO-UNIVERSAL sensors. Inquire to the factory or your local distributor for assistance with your application. For applications where a submersible type installation approach is used either an immersion tube is used to seal the rear MNPT threads on the sensor or a suitable waterproofing option with tubing (such as WPIT or WPB/WPH) is employed for full cable isolation in which case the sensor can be suspended by just by the cable assembly alone (without a guiderod). For typical inline installation schemes, a low-flow cell suitable for 1” NPT process lines is employed. | |

CALIBRATION INSTRUCTIONS OF AST-DO-UNIVERSAL-HiQDT DO SENSOR | |

Calibration of the AST-DO-UNIVERSAL-HiQDT sensor can be performed with the ASTI Windows Software, Handheld Communicator (HHC) or else from any modbus RTU master that has implemented the correct calls. Please refer to the documentation for the Windows Software, Handheld Communicator, or Touchscreen Controller for detailed instruction on how the calibration procedure is performed on each type of device. The gain calibration is performed when the sensor is clean and dry and exposed to only air. In cases of calibrations performed in air where the relative humidity is not 100%, the sensor should be suspended in air over a source of water for best results. It is necessary to wait for temperature and reading equalization (stabilization) before performing a calibration. Any robust long-life probe with a high stability thick membrane design and construction such as the AST-DO-UNIVERSAL dissolved oxygen sensor can take up to an hour to respond to a 10 °C change in air, whereas in water sensing this same change would take just 10 minutes. This must be taken into consideration in deciding when the probe is ready for calibration. ALWAYS perform a precise temperature calibration before doing any gain calibration. Calibration Tips: Take the probe up from the water process media, wipe the membrane dry, and hang the probe in free air, away from direct sunlight. If necessary, wrap aluminum foil around the AST-DO-UNIVERSAL sensor to avoid sunlight negatively impacting on the calibration. Be sure to wait for complete temperature equalization before performing the calibration described above. Calibration against various "pocket" test kits cannot be recommended. For greater accuracy, a correction for barometric air pressure can be entered in mmHg units using P05 in the setup menu. The salinity correction is recommended in salt water or brackish measured solutions to ensure that the computed % saturation is accurate. The salinity value is user entered in PSU (ppt) units and used in the computation of the percent (%) saturation value. The salinity value is NOT used during the calibration procedure as the sensor is not immersed in the brine solution but rather dry in air. In this way there exists two percent (%) saturation values. One percent (%) saturation value is solely for the purpose of calibration with the salinity value not used in the computation of the percent (%) saturation value. This is called the percent (%) saturation value. The second normal percent (%) saturation value DOES include the salinity value provided in the computation. Naturally if the salinity value is zero then these two percent (%) saturation values will be identical. At the completion of a proper calibration procedure the calibration percent (%) saturation will always read 100%. The salinity value of the measured solution can be determined from a handheld portable conductivity meter that can display the readings in salinity PSU/PPT units. It is also possible to convert from mS conductivity units to PSU units (contact factory for assistance if required). | |

How often should calibration be performed? | |

| Unfortunately, it is not possible to answer this question in a simple way. Under ideal conditions (in air) the probe can keep its calibration for many months. When used in water the actual conditions (e.g. the nature of deposit build-up) and desired accuracy will dictate calibration frequency. It is very important that calibrations are performed with care giving the probe time to stabilize and checking the barometer to enter the air pressure. Check salinity if you measure in salt or brackish type of solutions. It is important to remember that no continuous process measurement can ever be more accurate than the calibration performed before installation. | |

Maintenance | |

The probe's membrane must be kept free from deposits. A film composed mostly of bacteria will cover ALL surfaces in a biologically active system. This bacteria film acts as a diffusion barrier for the oxygen that must diffuse through the membrane. For industrial type process solution the most likely form of contamination and build-up will be particulates and solids from the solution if the media has high turbidity or viscosity or is an abrasive slurry in nature. The membrane must, therefore, be cleaned at regular intervals, the frequency depending on the actual conditions. Cleaning can be performed with a cloth or soft paper. The membrane is strong and not easily damaged, but do not try to scratch it clean with a fingernail! There is no need to exchange the electrolyte regularly, and there is no sensor element that will need replacing! The probe should not be taken apart for membrane replacement and rebuilding of the DO cell unless the membrane is damaged, or you cannot calibrate to the correct value after long use. Other Points Worth Considering Even though the AST-DO-UNIVERSAL dissolved oxygen probe is very robust, it should be treated carefully. It measures of few thousandths of a gram of oxygen, which it must "drag" out of the water around it. So, if, in your opinion, it performs mysteriously then ask the ASTI factory or your local agent/distributor for assistance. Best Practice Stocking Spare membranes, O-rings and electrolyte for the first few years' use are shipped with the probe, after which you can purchase more. A stock of these parts will enable you to replace a damaged membrane in a few minutes. If desired you can also stock a spare probe in which case you will then be able to replace a probe that is accidentally mechanically destroyed, damaged or lost. A spare probe can be kept ready-to-use for years at a time if stored in the proper manner and conditions. Spare probes should be stored in a cool, dry place without any electrolyte (filling solution) in the cap (completely dry). When a dry, unfilled spare probe is taken from stock for use, follow the steps outlined on the following page to get it ready for installation. A stock of one or more spare caps will make it easy to renovate probes with damaged or “old” membranes. You can fit new membranes to the “old” caps indoors in the dry conditions ready for next time. Spare Parts & Optional Fittings Set of 10 each thick high stability membrane with small O-rings

| |

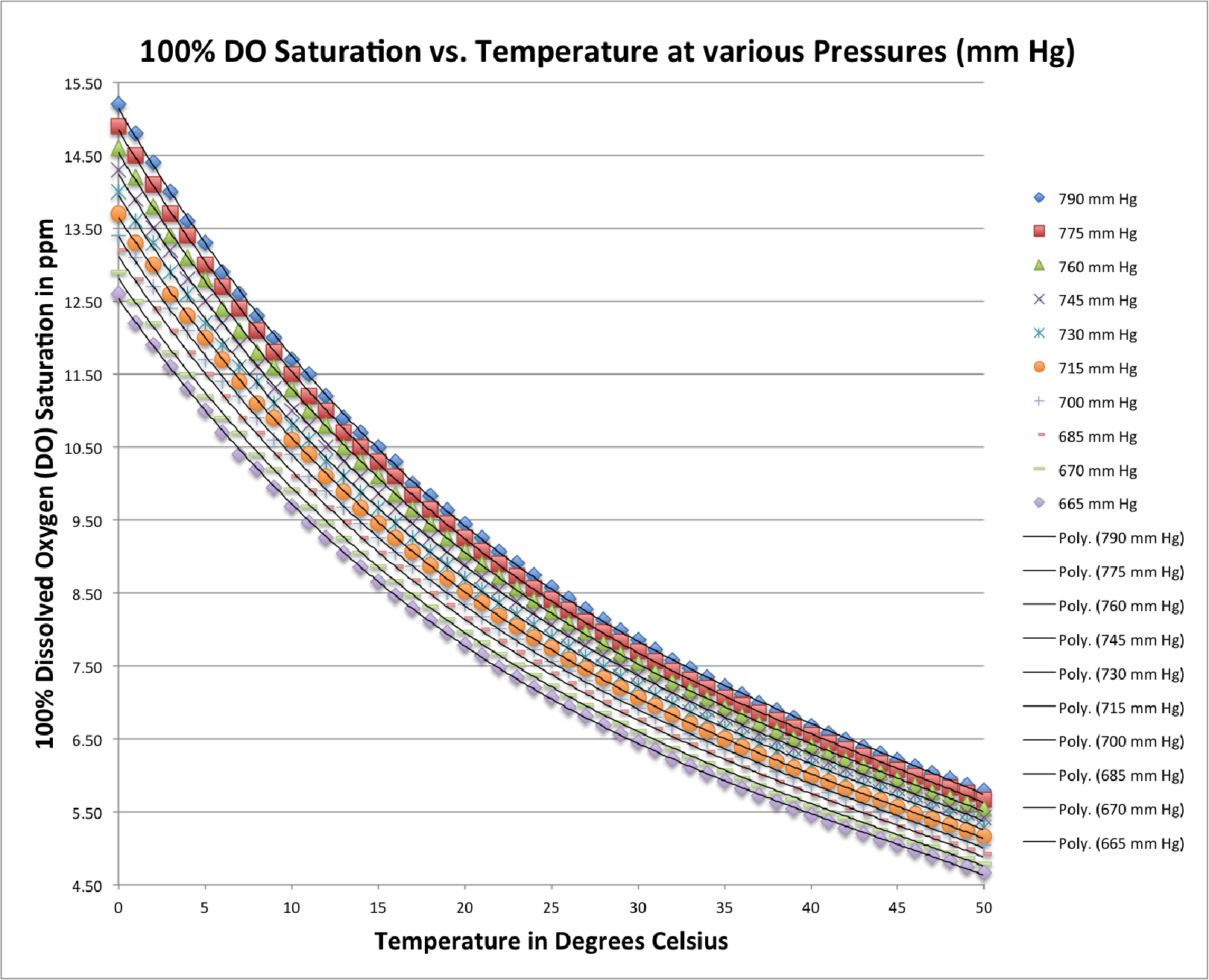

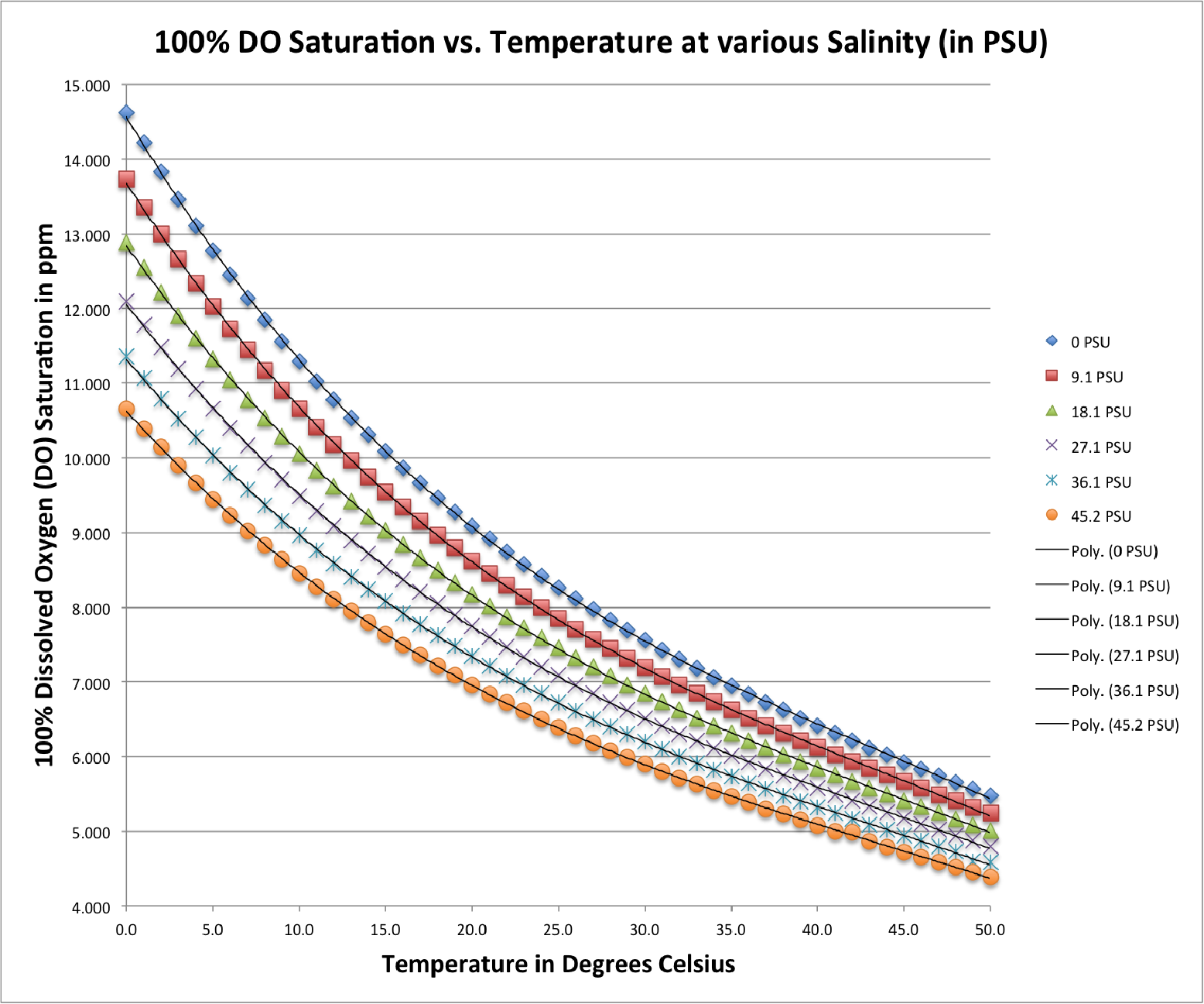

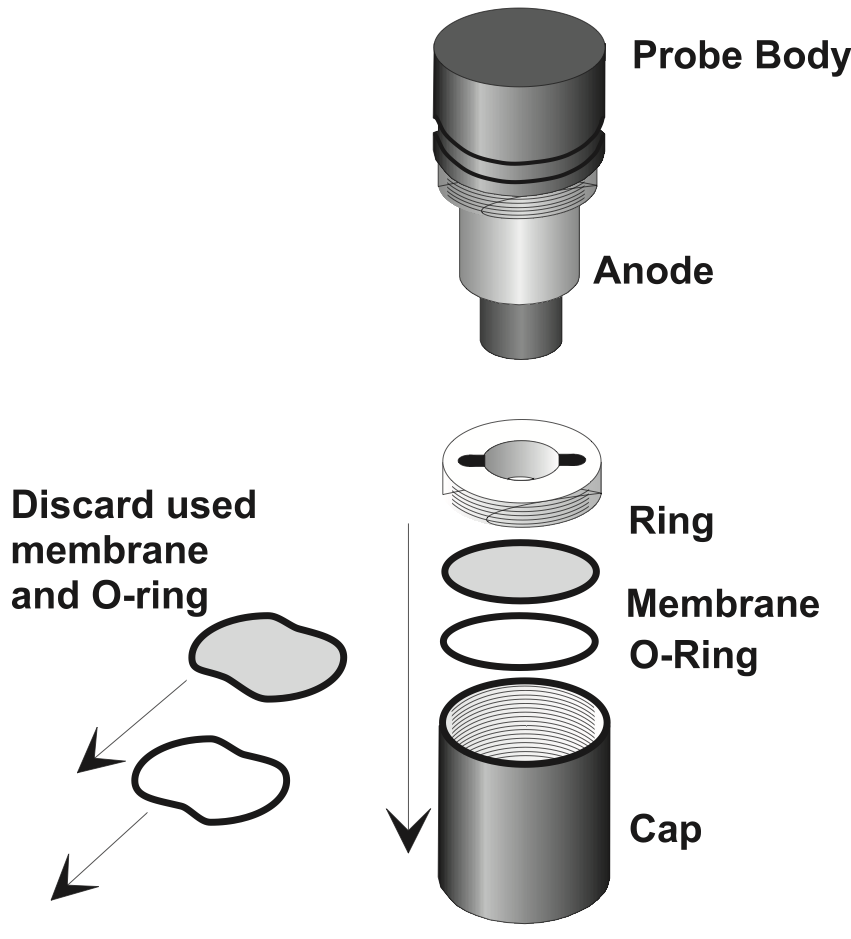

Automatic Calculation of Theoretical 100% Dissolved Oxygen Saturation at any Temperature & Pressure for Accurate Calibration & MeasurementThe HiQDT-DO sensor has preprogrammed the correct 100% dissolved oxygen saturation levels valid at any temperature and pressure. This is important for two main purposes: 1) to ensure accurate calibration of the sensor which is performed dry in air and 2) when the percent (%) saturation is displayed and output for purposes of monitoring and control. The graph below demonstrates the impact of both temperature and pressure on the dissolved oxygen (DO) ppm levels that constitute 100% saturation condition.  For the calibration function, either the field condition should be 100% relative humidity for best accuracy or else the sensor should be suspended dry in air but over a water source to simulate locally the 100% relative humidity condition. The water molecule in air (humidity) is then saturated with oxygen in manner that can be fully described by the ambient temperature and pressure as shown above. When placed into service, the galvanic DO sensor will measure the ppm levels at the installation depth. To convert this measured ppm value into percent (%) saturation the HiQDT-DO sensor uses the internally stored curve visualization above. Automatic Calculation of Theoretical 100% Dissolved Oxygen Saturation at any Temperature & Pressure for Accurate Calibration & MeasurementThe HiQDT-DO has preprogrammed the correct 100% dissolved oxygen saturation levels valid at not only any temperature and pressure but also corrected for salinity. This is important for applications where not only fresh water will be present but also for brackish and salt water sources in variable amounts. The graph below demonstrates the impact of salinity on the dissolved oxygen (DO) ppm levels that constitute 100% saturation condition at the nominal 760mm pressure condition. For simplicity of visualization just one set of curves is shown although the analyzer can perform this compensation any temperature, pressure or salinity.  This salinity correction is only required as a correction to the computation of the % saturation from the measured DO ppm levels for the inline measurement. Since the calibration is done dry in air, salinity correction is not required for this part of operation. Since the impact of salinity is considerable as shown in the graph above, it must be corrected carefully at any level of salinity and temperature. The salinity value in standard PSU (PPT) units can be entered into the HiQDT-DO sensor to perform this correction. The value of the salinity can be determined by a handheld meter or else monitoring continuously using a conductivity transmitter from which one can readily convert into common salinity units. Membrane Replacement of AST-DO-UNIVERSAL Industrial Galvanic Dissolved Oxygen (DO) Sensor

IMPORTANT NOTE BEFORE CHANGING MEMBRANE!

PREPARATION FOR CHANGING MEMBRANE

QUICK TEST | |

| MEMBRANE REPLACEMENT PROCEDURE: See drawing to right for all referenced components in instructions:

|

|